Wholesale Pillow Bag Forming And Sealing Machine - Automatic Noodle Bundling Packing Line with Six Weighers – Hicoca

Wholesale Pillow Bag Forming And Sealing Machine - Automatic Noodle Bundling Packing Line with Six Weighers – Hicoca Detail:

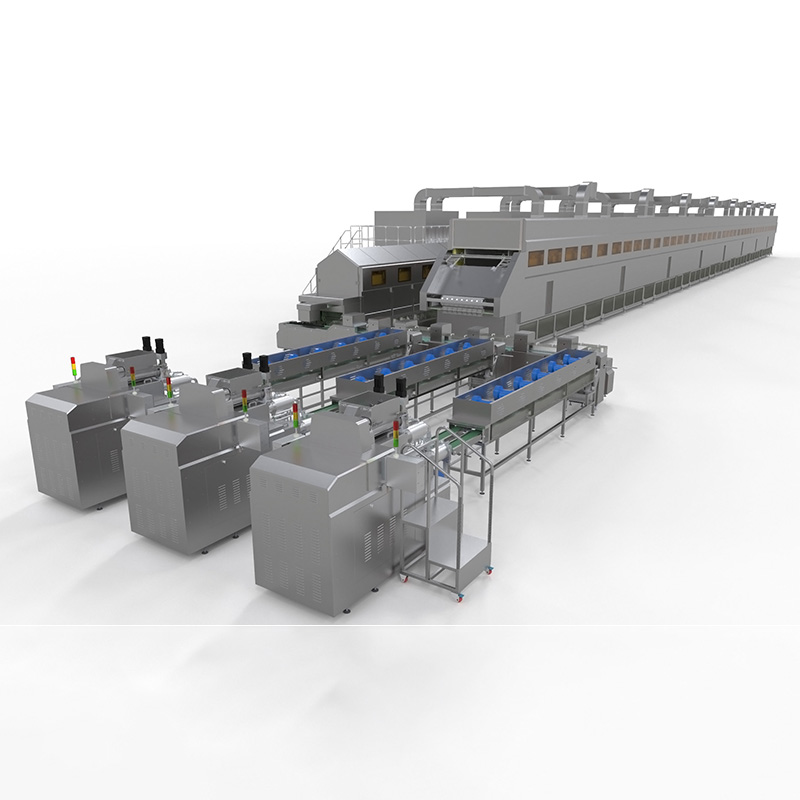

Automatic Noodle Bundling Packing Line with Six Weighers

Application:

The equipment is used for multi bundle plastic packaging of 180mm ~ 260mm long strips of food such as bulk noodles, spaghetti, pasta and rice noodle. The equipment completes the whole process of multi bundle packaging through automatic weighing, bundling, lifting, feeding, aligning, sorting, grouping, conveying, film forming, sealing and cutting.

Technical Parameter:

| Voltage | AC220V |

| Frequency | 50-60Hz |

| Power | 13KW |

| Air consumption | 3L/min |

| Measure accuracy | 50-150g/bundle ±2.0g 200 -300g/bundle ±3.0g |

| Packing specs | 200-250g/bundle, 4 bundles/bag; 75-150g/bundle, 4-5 bundles/bag. |

| Packing range | 300-1000g/bag |

| Packing speed | 15-40 bags/min |

| Bundling speed | 10-23 bundle/piece/min |

| Bundle type | Single belt; double-belt |

| Dimension | 15000x4600x1650mm |

Highlights:

1. The bundling & packing machine line adopts centralized electrical control, intelligent acceleration and deceleration, and reasonable human-computer interaction.

2. Each line only needs 2 ~ 4 people on duty, and the daily packaging capacity is 15 ~ 40 tons, which is equivalent to the manual daily packaging capacity of about 30 people.

3. It adopts imported electrical components, host frequency speed regulation, servo motor to control sorting, grouping and packaging film transportation, with anti cutting and anti empty packaging functions.

4. It uses film to replace finished packaging bags, which saves material cost of 500-800CNY per day.

5. With accurate counting and good compatibility, it can pack any weight. Equipped with protective devices, the equipment is highly safe.

6. The production line can match four to twelve different quantities of weighing machines according to the demanded capacity.

About us:

We’re a DIRECT factory specialized in designing and manufacturing full sets of intelligent food production and packaging assembly lines, including intelligent equipments of feeding, mixing, drying, cutting, weighing, bundling, elevating, conveying, packaging, sealing, palletizing, etc. for dried and fresh noodle, spaghetti, rice noodle, incense stick, snack food and steamed bread.

With over 50000 square meters manufacturing base, our factory is equipped with the world’s advanced processing and manufacturing equipments such as laser cutting machining center imported from Germany, vertical machining center, OTC welding robot and FANUC robot. We have established a complete ISO 9001 international quality system, GB/T2949-2013 intellectual property management system and applied for more than 370 patents, 2 PCT international patents.

HICOCA has over 380 employees, including over 80 R&D personnel and 50 technical service personnel. We can design machines according to your requirements, help to train your staff and even send our engineers & technical staff to your country for after-sales service.

Pls feel free to contact us if you’re interested in any of our products.

Our products

Our products

Exhibitions

Patents

Our Foreign customers

FAQ:

1. Q: Are you trading company?

A: We are a manufacturer of food packing machines with 20 years experience, and more than 80 engineers who can design machines according to your special request.

2. Q: What is your machine packing for?

A: Our packing machine is for many kinds of food, chinese noodle, rice noodle, long pasta, spaghetti, incense stick, instant noodle, biscuit , candy, sause, powder, ect

3. Q: How many countries have you exported to?

A: we have exported to more than 20 countries, such as : Canada, Turkey, Malaysia, Holland, India, etc.

4. Q: What is your delivery time?

A: 30-50days. For special request, we can deliver the machine within 20 days.

5. Q: What about aftersales service?

A: we have 30 aftersales service staff, who have experiene to provide service overseas to assemble the machines and train the customers’ workers when machines arrive.

Product detail pictures:

Related Product Guide:

Sticking for the principle of "Super Quality, Satisfactory service" ,We have been striving for being a superb small business partner of you for Wholesale Pillow Bag Forming And Sealing Machine - Automatic Noodle Bundling Packing Line with Six Weighers – Hicoca , The product will supply to all over the world, such as: Brisbane, Swiss, Egypt, Actually need to any of those objects be of interest to you, make sure you allow us to know. We'll be delighted to present you a quotation on receipt of one's comprehensive specs. We've our individual specialist R&D enginners to meet any of the requriements, We look forward to receiving your enquires soon and hope to have the chance to work together with you inside the future. Welcome to take a look at our organization.

In China, we have purchased many times, this time is the most successful and most satisfactory, a sincere and realiable Chinese manufacturer!