Trending Products Atta Chow Mein Packing Equipment - Automatic 3D M-Shape Bag Noodle Packaging Machine – Hicoca

Trending Products Atta Chow Mein Packing Equipment - Automatic 3D M-Shape Bag Noodle Packaging Machine – Hicoca Detail:

1. With Omron PLC and touch screen

2. With Magic Eyes tracing

3. With Servo motors controlling

M-shape bags packing machine 1 set,

conveyor line 1 set,

weighing machine 3 sets,(1 to 4 sets can be chosen according to your request.)

lifting engine 3 sets,

pneumatic linking bucket 3 sets

| Object | noodle, Spaghetti, pasta,rice noodle | |

| length of the noodle |

|

|

| thickness | 0.6~1.4mm | |

| width of the noodle | 0.8~3.0mm | |

| packing rate | 30~55bags / min | |

| weight range | 200~500g 200~1000g | |

| Inputting method | number input | |

| variable setting | 0.1g | |

| exact value | 400~1000g, ± 3.0g, percent of pass ≥ 96% | |

| size | 6050mm× 3200mm× 1650mm | |

| voltage | AC220v/50-60Hz/7000W |

Application:

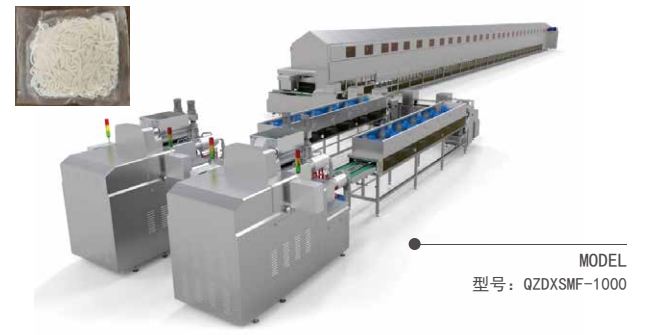

This equipment is suitable for M-shaped three-dimensional bag forming and packaging of 180~260mm long bulk noodle, spaghetti, pasta, rice noodle and other materials. Automatic weighing, bag making, lifting, conveying and other steps to achieve the entire process of automatic three-dimensional bag packaging.

Highlights:

1. Solid forming: As our patented equipment, it realizes the automatic production of top grade three dimensional packaging.

2. Automatic bag making with film achieves different packages varied from 400g to 1000g and reduces costs of labor and film.

3. Reciprocating horizontal sealing makes the sealing dog-ears beautiful.

4. Electrical anti-cutting avoids injury to staff and equipments

5. Function of empty bags detection can prevent empty bags effectively and save the cost of film.

6. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

About us:

We’re a DIRECT factory specialized in designing and manufacturing full sets of intelligent food production and packaging assembly lines, including intelligent equipments of feeding, mixing, drying, cutting, weighing, bundling, elevating, conveying, packaging, sealing, palletizing, etc. for dried and fresh noodle, spaghetti, rice noodle, incense stick, snack food and steamed bread.

With over 50000 square meters manufacturing base, our factory is equipped with the world’s advanced processing and manufacturing equipments such as laser cutting machining center imported from Germany, vertical machining center, OTC welding robot and FANUC robot. We have established a complete ISO 9001 international quality system, GB/T2949-2013 intellectual property management system and applied for more than 370 patents, 2 PCT international patents.

HICOCA has over 380 employees, including over 80 R&D personnel and 50 technical service personnel. We can design machines according to your requirements, help to train your staff and even send our engineers & technical staff to your country for after-sales service.

Pls feel free to contact us if you’re interested in any of our products.

Our products

Our products

Exhibitions

Patents

Our Foreign customers FAQ:

FAQ:

1. Q: Are you trading company?

A: We are a manufacturer of food making and packing machines with 20 years experience, and more than 80 engineers who can design machines according to your special request.

2. Q: What is your machine packing for?

A: Our packing machine is for many kinds of food, chinese noodle, rice noodle, long pasta, spaghetti, incense stick, instant noodle, biscuit , candy, sause, powder, ect

3. Q: How many countries have you exported to?

A: we have exported to more than 20 countries, such as : Canada, Turkey, Malaysia, Holland, India, etc.

4. Q: What is your delivery time?

A: 30-50days. For special request, we can deliver the machine within 20 days.

5. Q: What about aftersales service?

A: we have 30 aftersales service staff, who have experiene to provide service overseas to assemble the machines and train the customers’ workers when machines arrive.

Product detail pictures:

Related Product Guide:

We continuously execute our spirit of ''Innovation bringing development, Highly-quality ensuring subsistence, Management advertising and marketing gain, Credit history attracting buyers for Trending Products Atta Chow Mein Packing Equipment - Automatic 3D M-Shape Bag Noodle Packaging Machine – Hicoca , The product will supply to all over the world, such as: Sydney, US, Qatar, The best and original quality for spare parts is a most important factor for transportation. We may stick on supplying original and good quality parts even a little profit earned. God will bless us to do kindness business forever.

The company comply with the contract strict, a very reputable manufacturers, worthy a long-term cooperation.