Short Lead Time for Kelp Noodles Packing Equipment - Single Layer High Speed Stick Noodle Cutting Machine – Hicoca

Short Lead Time for Kelp Noodles Packing Equipment - Single Layer High Speed Stick Noodle Cutting Machine – Hicoca Detail:

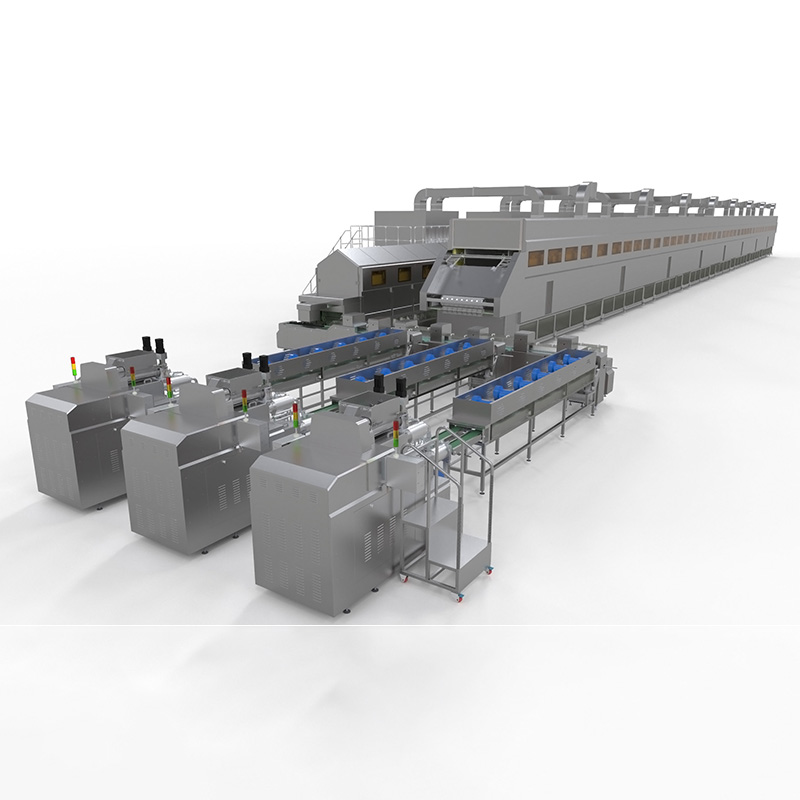

It is composed of racking machine, shaping machine, multi-knife or intelligent single-knife noodle cutter, electrical control cabinet, etc. After ~5 hours of drying, the noodles like a straight line are removed from the hook by the anchor chain and sent to the noodle cutter to be cut into Each section (length 100mm-300mm can be adjusted), package the product with the required weight after measurement.

Contains

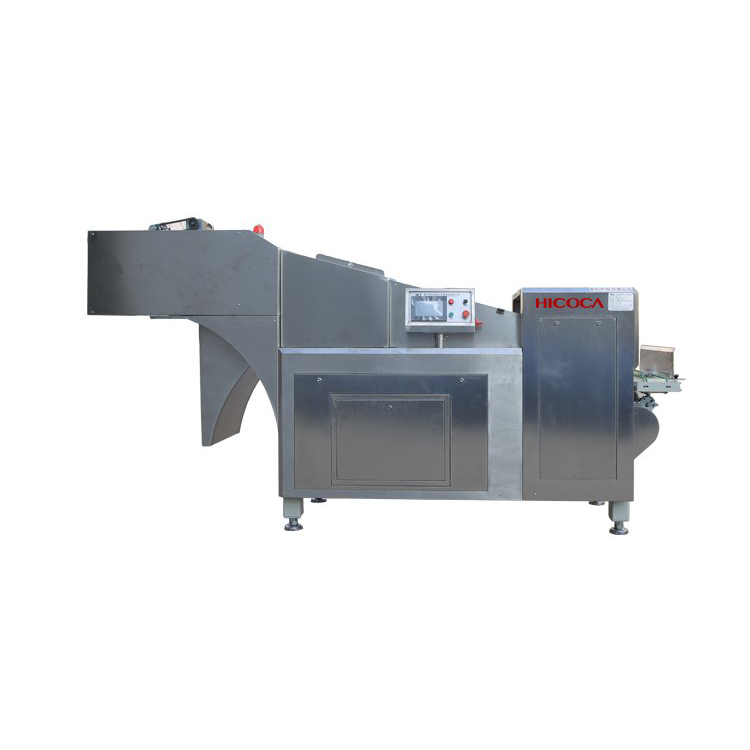

1, cutting device —one set

2, noodle unloading device —one set

3, conveyor —one set

Application: Connecting with noodle production line, automatically finish the process of cutting noodle to the requested length.

Advantage:

1, cutting length controlled with servo motor, easy setting and operating ,high accuracy.

2, straight cutting without any fragment,with high cutting accuracy

3, with the extremity separating device, avoid the extremity be packed into the package.

Technical specification

| Voltage: | AC220V |

| Frequency: | 50-60Hz |

| Power: | 3; 4.5(1500)kw |

| Gas consuming: | 3L/min |

| Cutting speed: | 14-18 times/min |

| Cutting size: | 180-260mm |

| The maximum size of the machine: | 370*2150*1500mm |

The main parameters

Roller width: 350mm

Capacity: up to 500kg flour/hour

Power; 5.5kw

Equipment size: length 2000×width 1020×height 1510mm

Operation environment

Site requirements: The equipment should be established inside the room with flat floor. No shaking and bumping.

Floor requirements: it should be hard and non-conductive.

Temperature: -5~40℃

Relative humidity: <75%RH, no condensation.

Dust: no conductive dust.

Air: no flammable and combustible gas or objects,no gas which can make damage to mental.

Altitude: under 1000 meters

Ground connection: safe and reliable ground environment.

Power grid: stable power supplying, and volatility within +/-10%.

Other requirements: keep away from rodents

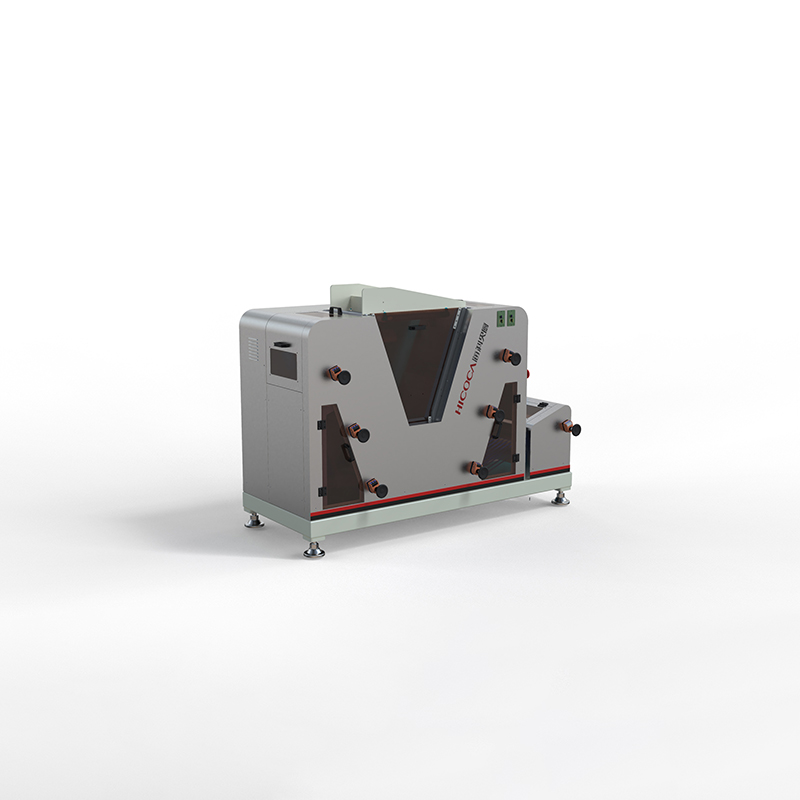

Product detail pictures:

Related Product Guide:

Our personnel are generally within the spirit of "continuous improvement and excellence", and using the excellent top quality goods, favorable rate and superior after-sales expert services, we try to win every customer's believe in for Short Lead Time for Kelp Noodles Packing Equipment - Single Layer High Speed Stick Noodle Cutting Machine – Hicoca , The product will supply to all over the world, such as: Istanbul, Munich, Peru, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.