Renewable Design for Noodle Packaging Packing Line - Metal detector – Hicoca

Renewable Design for Noodle Packaging Packing Line - Metal detector – Hicoca Detail:

Applications

Metal detector can be used in the industry of food, medicine, toy, chemical and leather etc, to detect and remove the iron grain, needle, lead, copper, aluminum and stainless steel etc. It can be also associated the ma-chine with automatic product line.

Features

Advanced technology

Using DDS frequency synthesis, DSP digital signal processing, high efficiency power amplifier and other advanced technology, industry technology leader.

Super hardware configuration

Adopt double high speed digital signal processor design, have extremely high accuracy and fast processing speed.

Product effect inhibiting

Using multiple frequency design, intelligent self learning, the three dimensional testing and other advanced technology, effectively restrain the product effect, wide range of detection.

Easy operation

The wide LCD and wizard-style interface, users can quickly and easily for setup and operation.

Data safe and reliable

The secondary user security management mode and the FRAM safety storage technology, ensure the security of the system parameters and data

Reasonable structure ,meet the requirements of food grade

Frame and main parts made of 304 stainless steel,conveyor use the food grade PU belt, facilitate cleaning maintenance.

Parameters

|

Model |

|

HMD2010 |

|

Szie of detector window |

W(mm) |

260 |

|

H(mm) |

100 |

|

|

Szie of biggest products |

W(mm) |

200 |

|

H(mm) |

70 |

|

|

Detection accuracy |

Fe(mm) |

0.8-1.5 |

|

Non Fe(mm) |

1.0-1.5 |

|

|

|

SuS(mm) |

1.5-2.5 |

|

Height of belt (mm) |

700 |

|

|

Width of belt(mm) |

200 |

|

|

Maximum transmission weight(kg) |

1 |

|

|

Speed of belt(m/min) |

28 |

|

|

Alarm way |

Alarm |

|

|

Remove method |

Air injection |

|

|

Power |

Single220V AC 50~60Hz 120-180W, | |

|

Size (mm) |

1200*600*950 |

|

|

Weight(kg) |

220 | |

Note:The above detection accuracy is the highest accuracy of tested products without product effect

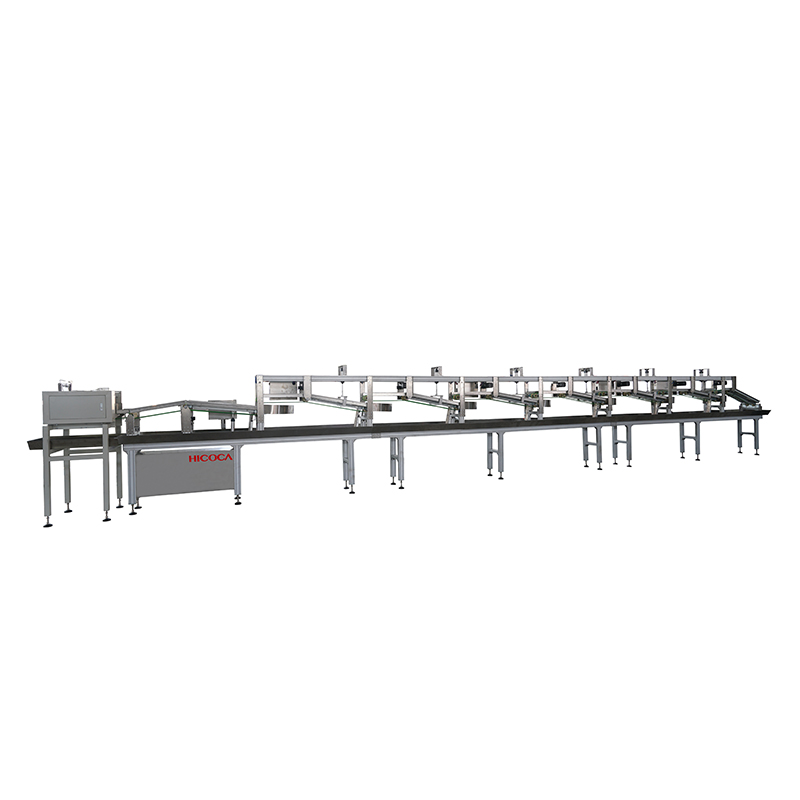

Product detail pictures:

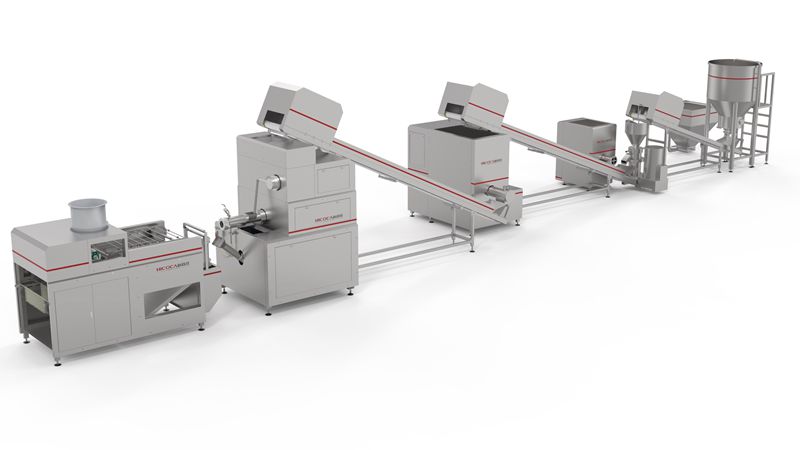

Related Product Guide:

Always customer-oriented, and it's our ultimate target to be not only the most reliable, trustable and honest supplier, but also the partner for our customers for Renewable Design for Noodle Packaging Packing Line - Metal detector – Hicoca , The product will supply to all over the world, such as: Greenland, Brunei, Holland, We believe with our consistently excellent service you can get the best performance and cost least goods from us for a long term . We commit to provide better services and create more value to all our customers. Hope we can create a better future together.

The factory workers have a good team spirit, so we received high quality products fast, in addition, the price is also appropriate, this is a very good and reliable Chinese manufacturers.