Renewable Design for Noodle Packaging Packing Line - High Speed Automatic Noodle Weighing Machine – Hicoca

Renewable Design for Noodle Packaging Packing Line - High Speed Automatic Noodle Weighing Machine – Hicoca Detail:

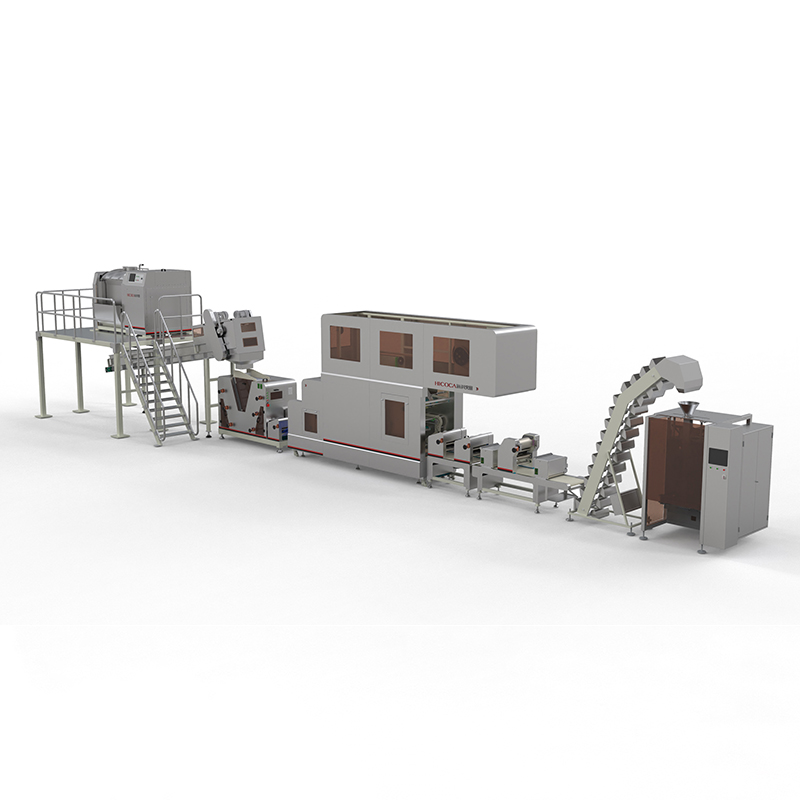

High Speed Automatic Noodle Weighing Machine

Application:

The equipment is mainly used for weighing long strips of food such as dry noodle, spaghetti, rice noodle, long pasta, etc. It can accurately weigh different weights according to requirements and cooperate with bundling machine, elevator, feeding system and packaging machine. It can be used alone or connected.

Technical Specification:

| Voltage | AC220V |

| Frequency | 50Hz |

| Power | 2KW |

| Weighing Range | 300~1000 ±2.0g, 50~500 ±2.0g |

| Weighing speed | 30-50 times/min |

| Dimension(L x W x H) | 3900 × 900×2200mm |

Highlights:

1. It can be used together with ordinary packaging machine and three-dimensional bag packaging machine, and the accurate weighing can be completed by the combination of rough and fine weighing.

2. With the unique design of automatic feeding system for fine weighing, the manipulator grabs materials from the rough weighing bin and automatically puts them into the fine weighing bin, which is 70% faster than that of ordinary weighing machine.

3. The elevated design facilitates people and logistics to pass through without obstacles, saves material and personnel flow time and speeds up the circulation efficiency of the workshop.

4. It is equipped with double feeding ports, which can complete the cooperation of the two feeding ports and the following conveying machines at the same time, so as to realize orderly and rapid automatic weighing.

Working conditions:

Site requirements: flat floor, no shaking or bumping.

Floor requirements: hard and non-conductive.

Temperature: -5~40ºC

Relative humidity: <75%RH, no condensation.

Dust: no conductive dust.

Air: no flammable and combustible gas or objects, no gas, which can make damage to mental.

Altitude: under 1000 meters

Ground connection: safe and reliable ground environment.

Power grid: stable power supplying, and volatility within +/-10%.

Other requirements: keep away from rodents

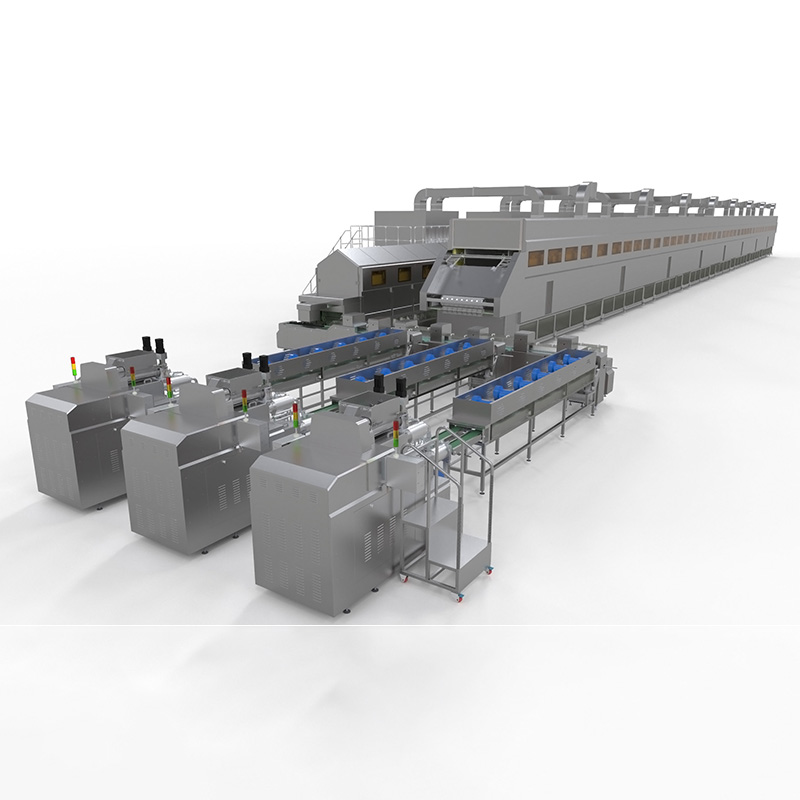

Related packing Line:

About us:

We’re a DIRECT factory specialized in designing and manufacturing full sets of intelligent food production and packaging assembly lines, including intelligent equipments of feeding, mixing, drying, cutting, weighing, bundling, elevating, conveying, packaging, sealing, palletizing, etc. for dried and fresh noodle, spaghetti, rice noodle, incense stick, snack food and steamed bread.

With over 50000 square meters manufacturing base, our factory is equipped with the world’s advanced processing and manufacturing equipments such as laser cutting machining center imported from Germany, vertical machining center, OTC welding robot and FANUC robot. We have established a complete ISO 9001 international quality system, GB/T2949-2013 intellectual property management system and applied for more than 370 patents, 2 PCT international patents.

HICOCA has over 380 employees, including over 80 R&D personnel and 50 technical service personnel. We can design machines according to your requirements, help to train your staff and even send our engineers & technical staff to your country for after-sales service.

Pls feel free to contact us if you’re interested in any of our products.

Our products

Our products

Exhibitions

Patents

Our Foreign customers

FAQ:

1. Q: Are you trading company?

A: We are a manufacturer of food making and packing machines with 20 years experience, and more than 80 engineers who can design machines according to your special request.

2. Q: What is your machine packing for?

A: Our packing machine is for many kinds of food, chinese noodle, rice noodle, long pasta, spaghetti, incense stick, instant noodle, biscuit , candy, sause, powder, ect

3. Q: How many countries have you exported to?

A: we have exported to more than 20 countries, such as : Canada, Turkey, Malaysia, Holland, India, etc.

4. Q: What is your delivery time?

A: 30-50days. For special request, we can deliver the machine within 20 days.

5. Q: What about aftersales service?

A: we have 30 aftersales service staff, who have experiene to provide service overseas to assemble the machines and train the customers’ workers when machines arrive.

Product detail pictures:

Related Product Guide:

We provide good power in high-quality and progress,merchandising,revenue and internet marketing and operation for Renewable Design for Noodle Packaging Packing Line - High Speed Automatic Noodle Weighing Machine – Hicoca , The product will supply to all over the world, such as: Salt Lake City, Canberra, Kyrgyzstan, Good quality and reasonable price have brought us stable customers and high reputation. Providing 'Quality Products, Excellent Service, Competitive Prices and Prompt Delivery', we are now looking forward to even greater cooperation with overseas customers based on mutual benefits. We will work whole-heartedly to improve our products and services. We also promise to work jointly with business partners to elevate our cooperation to a higher level and share success together. Warmly welcome you to visit our factory sincerely.

A nice supplier in this industry, after a detail and careful discussion, we reached a consensus agreement. Hope that we cooperate smoothly.