products

-

Full automatic palletizer

Product name: Full automatic palletizer

Item No#: HKJTPK-1

-

Dough sheeting machine

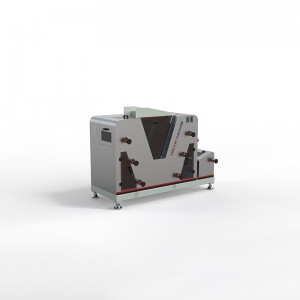

Equipment name: dough sheeting machine

Device model: HKYC-PXYY-01

-

Automatic Pasta Spaghetti Noodle Weighing Packing Machine with Three Weighers

It is mainly used for packing of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The packing process is completed through automatic weighing, output, filling and sealing.

1. This is the patented equipment of our factory HICOCA. Round film package facilitates the automation of reorganization, encasement, bagging, storage and transportation of the contents like noodle, spaghetti, etc. In addition, it can protect them from breaking.

2. Packing accuracy is highly enhanced by the high speed motion controller and high precision servo driving system. It’s stable and durable.

3. It can be operated by one person only and greatly reduces the labor and packaging costs. The daily capacity is 36-48 tons.

4. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

-

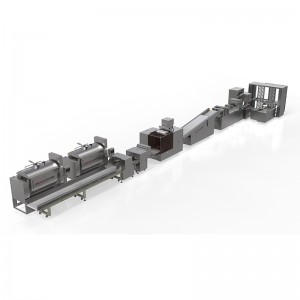

Automatic Noodle Bundling Packing Line with Six Weighers

The packing line is used for multi bundle plastic packaging of 180mm ~ 260mm long strips of food such as bulk noodles, spaghetti, pasta and rice noodle. The equipment completes the whole process of multi bundle packaging through automatic weighing, bundling, lifting, feeding, aligning, sorting, grouping, conveying, film forming, sealing and cutting.

1. The bundling & packing machine line adopts centralized electrical control, intelligent acceleration and deceleration, and reasonable human-computer interaction.

2. Each line only needs 2 ~ 4 people on duty, and the daily packaging capacity is 15 ~ 40 tons, which is equivalent to the manual daily packaging capacity of about 30 people.

3. It adopts imported electrical components, host frequency speed regulation, servo motor to control sorting, grouping and packaging film transportation, with anti cutting and anti empty packaging functions.

4. It uses film to replace finished packaging bags, which saves material cost of 500-800CNY per day.

5. With accurate counting and good compatibility, it can pack any weight. Equipped with protective devices, the equipment is highly safe.

6. The production line can match four to twelve different quantities of weighing machines according to the demanded capacity. -

Automatic Flat Bag Packing Machine

The machine is suitable for the flat bag collective packing of single bags of products with long strips such as stick noodle, spaghetti, rice noodles, vermicelli and Yuba. The whole process of fully automatic flat bag packing is completed through automatic feeding, sorting, bagging and sealing.

-

Packing machine450-120

Two sets of servo motors. One drives chain conveyor and end sealer, another drives film and long sealer.

PLC+HMI components. Bi-lingual (Chinese and English) instructions. Packing speed, length, temperature, control method can by chosen through HMI by numbers.

Double tracking method. Photo-sensor working together with servo system can realize automatic controlling according to the color code on the film, to make sure the cutting accuracy. -

Automatic Double-Layer Noodle Cutting Machine

This machine is designed to cut noodles, pasta, spaghetti, rice noodles.

1. The double layers can work synchronically as well as independently. The cutting machine can keep operating even during maintenance. The width of cutting section can reach to 1500mm and the production efficiency is improved by 30%.2. The function of rod clearance can remove the broken noodles sticking to the rod and the rod can return back to the revolving area automatically. That can reduce labor intensity, save time and avoid secondary pollution.

3. Easy operation, one touch start and with servo motors to ensure the accuracy of cutting length makes it a wonderful choice.

-

Automatic Semi Dry Rice Noodle Making Machine Production Line

With rice as the main raw material, the water content of the semi dry rice noodle cake is 42-45%. Packaged in composite film bags, the shelf life after preservation treatment can reach 6 months.

1. Product specification: 160-200g / bag, 4320 bags / h, and the production capacity is 650-850kg / h.

2. 10 hours per shift, 9 hours of production, 13 employees per shift, the yield is 14T of semi dry rice noodles in two shifts. -

Metal detector

Metal detector can be used in the industry of food, medicine, toy, chemical and leather etc, to detect and remove the iron grain, needle, lead, copper, aluminum and stainless steel etc. It can be also associated the ma-chine with automatic product line.

-

Stick Noodle Papered wrapping and Packing Machine

The machine can pack spindly things with paper like noodles, spaghetti, pasta. Can automatically finish the process of weighing, feeding, bounding, lifting&packing.

-

Intelligent Bionic Round Steamed Bread Production Line

Product model: MYM-180

-

Check weigher

This series check weigher is a kind of high speed and high precision online weight inspecting equipment, it’s mainly used for various automatic assembly line and logistical conveyor system to check low or high weight deviation of the on-line products, then, to sort them. And it works with all kinds of packaging production line and conveying system.