products

-

Intelligent bionic dumpling production line

Product model:JCX-3/180

Summary information:It is used in the automated production of dumplings and wontons, realizing a fully automated production process from flour supply to dumpling forming.

Applicable products:Dumpling, wonton

Production location:Qingdao China

-

Commercial Udon Making Machine

Product model:BWD-12.5

Summary information:It is suitable for the production of udon noodles, hand-rolled noodles and buckwheat noodles. It integrates noodle mixing, noodle pressing, noodle rolling, noodle cutting and noodle collecting. It adopts traditional manual bionic noodle making technology. It is suitable for noodle shops, canteens, supermarkets, fresh noodle shops, chain restaurants, central kitchens, etc.

Applicable products:Udon, hand-rolled noodles, soba noodles, etc.

Production location:Qingdao China

-

Fully Automatic Snail Rice Noodle production line

Product model:QZDLSF-750

Summary information:

The production line is suitable for the industrial production of rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc., meeting the fully automatic process from rice feeding to forming and cutting. The production line products use rice as the main raw material, with a moisture content of 14-15%, meeting the product demand of 18 months of shelf life after preservation treatment.

Applicable products:Rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc.

Production location:Qingdao China

-

Fully Automatic Straight Dried Rice Noodle production line

Product model:QZDZTMF-750

Summary information:

The production line is suitable for the industrial production of rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc., and meets the fully automatic process from rice mixing to finished products. With rice as the main raw material, the water content is 14~15%, the shelf life is 18 months, and the diameter is 0.8mm-2.0mm.

Applicable products:

Rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc.

Production location:Qingdao China

-

Fully Automatic Straight Fresh Wet Rice Noodle production line

Product model:QZDZTXF-1000

Summary information:

This production line is suitable for the industrial production of rice noodles such as Jiangxi rice noodles, Guilin rice noodles, Liuzhou snail noodles, Changde rice noodles, Yunnan cross-bridge rice noodles, etc. It meets the full automatic process from rice feeding to forming and cutting.

Applicable products:

Production line products; rice as the main raw material, with a moisture content of 66% to 70%, and are packaged in composite film bags to meet the product demand for a shelf life of 6 months after fresh-keeping treatment.

Production location:Qingdao China

-

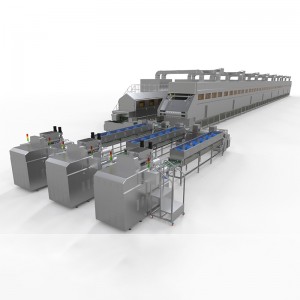

Fully automatic noodle production line

Product model:GMMX-450/650/765/800/900/1000/150型

Summary information:Suitable for the production of hanging noodles, instant noodles, and fresh wet noodles, achieving a fully automated production process from flour entering the warehouse to shredding and shaping.

Applicable products:Noodles, instant noodles, fresh wet noodles

Production location:Qingdao China

-

Automatic Bag Filling Sealing Packing Machine for Noodle

By selecting different measuring instruments, it’s suitable for the packaging of noodle, spaghetti, pasta, rice noodle, vermicelli, liquid, sauce, granules, powder, irregular blocks and other materials.

-

Two Weighers Automatic Noodle Packaging Machine

It is mainly used for packaging of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The packaging process is completed through automatic weighing, output, filling and sealing.

1. This is the patented equipment of our factory HICOCA. Round film package facilitates the automation of reorganization, encasement, bagging, storage and transportation of the contents like noodle, spaghetti, etc. In addition, it can protect them from breaking.

2. Packing accuracy is highly enhanced by the high speed motion controller and high precision servo driving system. It’s stable and durable.

3. It can be operated by one person only and greatly reduces the labor and packaging costs. The daily capacity is 36-48 tons.

4. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

-

Weighing and packing machine

1, bulk noodle packing machine: one set,

2, conveyor line: one set,

3, weighting machine: three set,

4,lifting engine (elevator):three set,

-

Full automatic bundling and packing machine

automatically finish the process of weighing , bundling, conveying and packing of the noodle and spaghetti.

-

Full-automatic fresh rice noodle production line

Product introduction Using rice as the main raw material, it produces fresh wet rice noodles with a moisture content of 66% to 70%. It is packaged in a composite film bag and can be stored for 6 months after preservation. Technological Process Mixing rice → micro-fermented soaked rice → filtering water → crushing rice → mixing flour → automatic feeding → maturing and extruding wire → cutting off fixed strip → checking weight → conveying → automatic boxing → aging → softening → Shapi... -

Intelligent Straight Rice Noodle Making Machine Production Line

The Rice Noodle intelligent production line achieves the automation of the whole line without manual assistance of rice soaking, crushing, extrusion, cutting, quantitiveness, sorting into boxes, aging, softening, disinfecting and drying. It greatly reduces the potential dangers of food safety, reduces labor intensity and improves the economic benefits of customers. It makes a breakthrough in the market.

With rice as the main raw material, the water content of the straight rice noodle is 14-15%, and the shelf life can reach 18 months.

Highlights:

1. Product specification: 0.8-2.5mm diameter of dry rice noodle, and the production capacity is 750-780kg / h.

2. 10 hours per shift, 9 hours of production, 15-16 employees per shift, the yield is 14 Tons of straight rice noodles in two shifts.