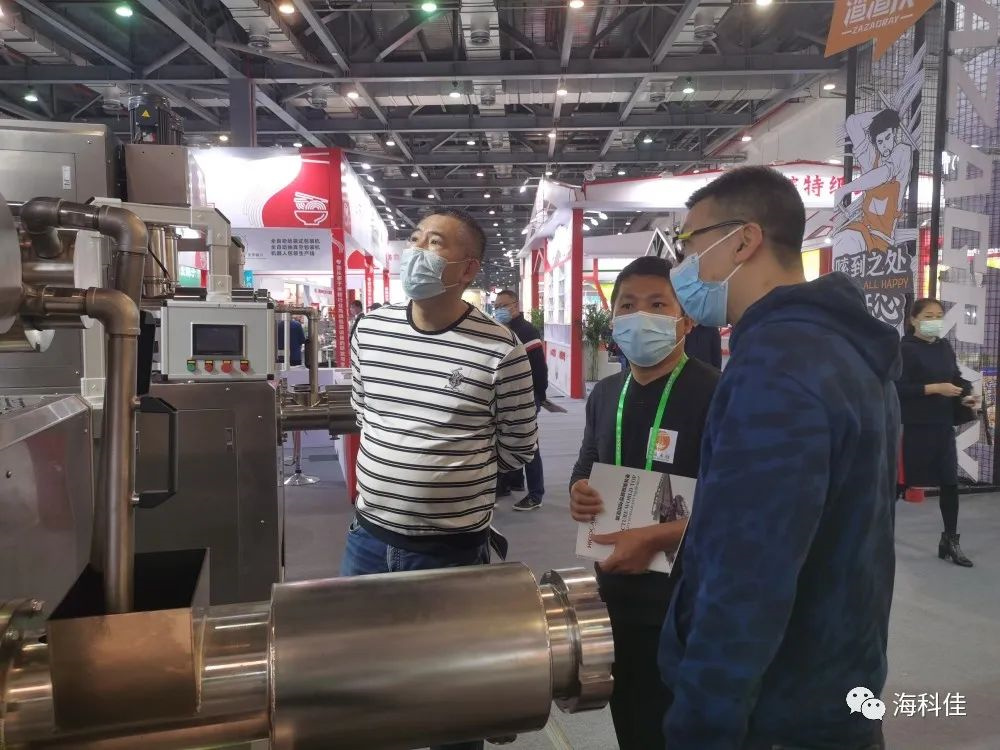

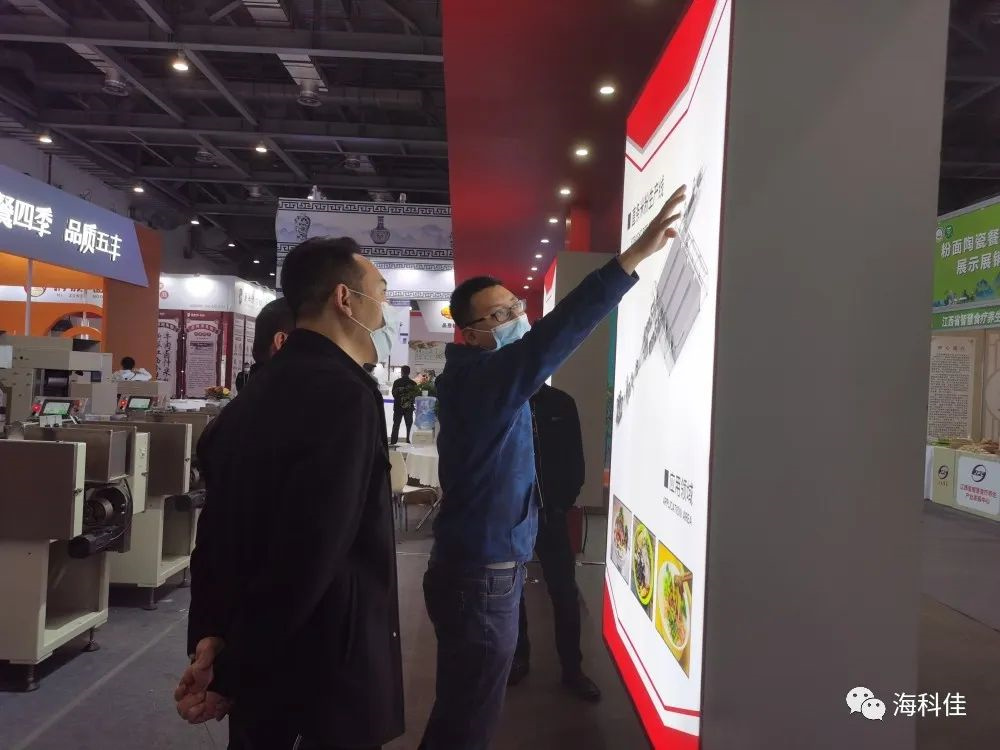

On November 24th, the 2nd China Rice Noodles Expo opened in Nanchang. The theme of the expo was “Expanding Domestic Demand and Promoting Development of Rice Noodles Industry”. It set up three major sections: forums, exhibitions and special events, with distinctive features and bright spots. Qingdao HICOCA / Haitejia brought equipment for rice noodle production and packaging to the Rice Noodle Expo. On the first day of the exhibition, HICOCA / Haitejia attracted great attention of many rice noodle practitioners.

The purpose of holding the China Rice Noodle E is to thoroughly implement the spirit of General Secretary Xi Jinping’s important instructions on the rice noodle industry. It continues to build a national rice noodle industry chain, innovation chain, and value chain for collaborative development, exchange and cooperation platforms, and boost the high-quality development of the rice noodle industry. The deep integration of the primary, secondary and tertiary industries of rice noodles will promote the standardization, branding, and large-scale development of the entire industry chain and further release the potential of commerce and consumption.

The Haitejia team has more than 30 years of experience in the production and research of different types of rice noodle technology and equipment. It uses ten years of mature rice noodle production technology into equipment. It cooperates with rice noodle production enterprises to upgrade and improve the overall production process with the best automatic and intelligent equipment of different categories of rice noodles.

The company has the first rice noodle process experiment production line and laboratory in the industry. HICOCA strives to verify the optimal production process at the fastest speed and realizes the development of rice noodle equipment, manufacturing and the improvement of traditional rice noodle technology.

Haiteji’s existing automatic rice noodle production line has two production modes: traditional layout automation connection and tunnel layout automation connection. Different production processes and equipment for pulping and flour milling, fermentation and non-fermentation are used to meet the needs of different customers.

On the basis of inheriting the traditional rice noodle production process, automatic production line makes rice noodle production simpler, more stable in quality, better in production environment, lower in labor intensity, better in production cost, higher in economic benefits, and more flexible and smooth in taste.

Post time: Nov-25-2022