Everyone feels that the production and consumption of noodles and instant noodles has spread to the southeast and northwest of the country, while the production and sales of rice noodles and instant rice noodles in the Northwest and Northeast are almost in their infancy.

What restricts the development of rice noodles, especially instant rice noodles?

We have to mention the five elements of making instant rice noodles:

1. Production equipment;

2. Formulation process;

3. Production process;

4. Sterilization process;

5. Anti-aging process.

Instant rice noodles are subdivided into three categories:

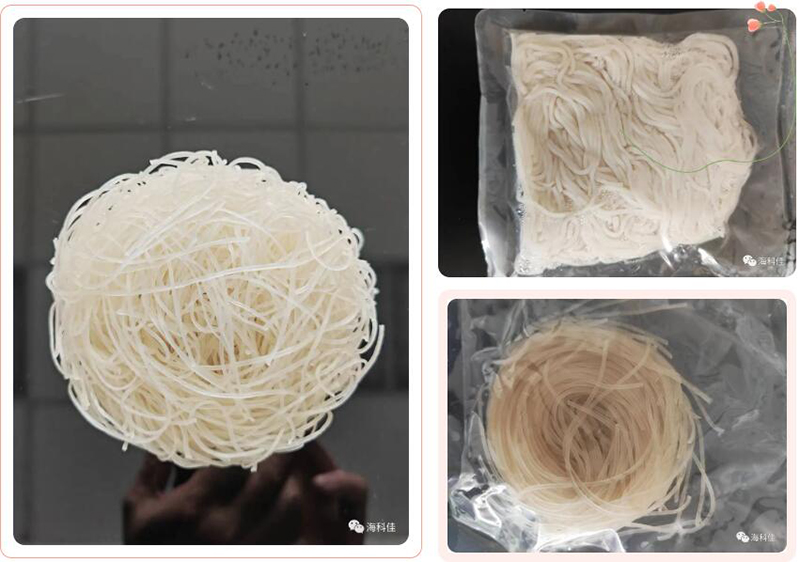

1. Brewing pan powder: powder diameter 0.7-1.2mm, water content 13.5-14.5%. It is produced by three different processes: cooked process, steamed material process and thin slurry process, and the quality difference is obvious.

2. Fresh wet rice noodles: powder diameter 1.5-2.5mm, water content 66-70%. It is produced by the cooking process and the steaming process, and the quality difference is obvious.

3. Semi-dry and wet rice noodles: powder diameter 1.2-2.2mm, water content 35-45%. It is produced by cooked process and slurry process. The quality difference is obvious.

The preparation process of each type of instant rice noodles is different, and the performance differences of the production equipment are very obvious. The degree of automation of the equipment largely depends on whether the equipment manufacturing enterprises have a thorough understanding of the production processes of different instant rice noodles.

“Steel becomes a machine with technology, and steel without technology” is a classic saying that equipment manufacturing relies heavily on technology.

To be well equipped, one must have a thorough understanding of rice noodle craftsmanship, and one must have the wisdom to create good craftsmanship.

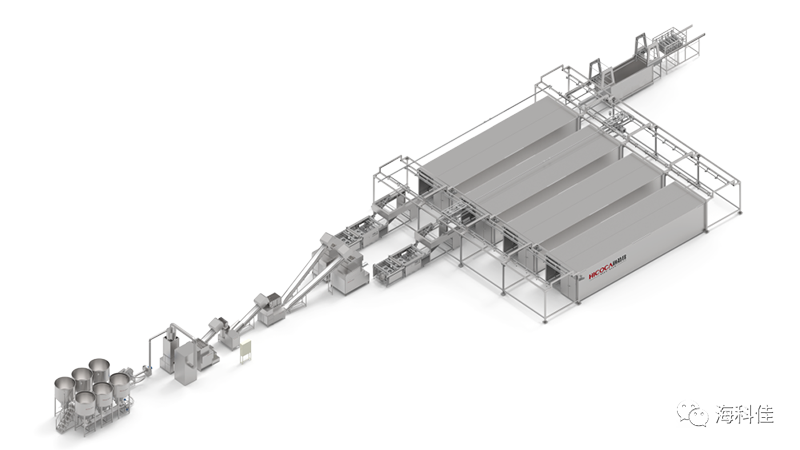

It has two production line modes: traditional layout automation connection and modern tunnel layout automation connection.

With fermentation and non-fermentation technology, pulping and grinding technology, steaming and cooking technology, high temperature aging and low temperature aging technology, chemical preparation, biological preparation and physical sterilization integration technology, hot wind energy and air energy baking technology, with the whole The different production techniques and equipments of Fangfang adapt to the production needs of different customers, which is the actual demand of the current rice noodle enterprises.

On the basis of inheriting the characteristics of the traditional rice noodle production process, the groundbreaking process and mechanical properties of the production line make the production of rice noodle easier, the quality more stable, the production environment better, the labor intensity lower, the production cost better and the economic benefit higher , the taste is more flexible and smooth. To replace the outdated semi-mechanical and semi-manual traditional production machinery with the best automatic and intelligent equipment of different categories, and cooperate with rice noodle production enterprises to carry out the overall layout, upgrade and improvement of rice noodle production technology and equipment is the current expectation of rice noodle enterprises. Where to look forward to.

On the basis of inheriting the characteristics of the traditional rice noodle production process, the groundbreaking process and mechanical properties of the production line make the production of rice noodle easier, the quality more stable, the production environment better, the labor intensity lower, the production cost better and the economic benefit higher , the taste is more flexible and smooth. To replace the outdated semi-mechanical and semi-manual traditional production machinery with the best automatic and intelligent equipment of different categories, and cooperate with rice noodle production enterprises to carry out the overall layout, upgrade and improvement of rice noodle production technology and equipment is the current expectation of rice noodle enterprises. Where to look forward to.

In order to meet the development needs of the instant rice noodle industry, the company team has spent several years doing a lot of research, study, and practice. Combining its own experience in the production of rice noodle for more than 30 years, it has verified the production techniques of various types of traditional rice noodle across the country. False to reality, weeding out the old to bring forth the new, infiltrating the bone marrow of production equipment with mature rice noodle production technology, guiding the research and development of equipment with standardized rice noodle production process parameters, manufacturing various types of rice noodle automated and intelligent production lines, and successfully realized the straight and half Dry and wet instant rice noodles, straight fresh and wet instant rice noodles, convenient brewing plate noodles, block semi-dry and wet instant rice noodles, block fresh and wet instant rice noodles, five different varieties of instant rice noodles. Production equipment from the bottom of the rice to the finished product packaging Automated and intelligent production functions .

In order to meet the development needs of the instant rice noodle industry, the company team has spent several years doing a lot of research, study, and practice. Combining its own experience in the production of rice noodle for more than 30 years, it has verified the production techniques of various types of traditional rice noodle across the country. False to reality, weeding out the old to bring forth the new, infiltrating the bone marrow of production equipment with mature rice noodle production technology, guiding the research and development of equipment with standardized rice noodle production process parameters, manufacturing various types of rice noodle automated and intelligent production lines, and successfully realized the straight and half Dry and wet instant rice noodles, straight fresh and wet instant rice noodles, convenient brewing plate noodles, block semi-dry and wet instant rice noodles, block fresh and wet instant rice noodles, five different varieties of instant rice noodles. Production equipment from the bottom of the rice to the finished product packaging Automated and intelligent production functions .

Equipment is just one of the five elements of making instant rice noodles. How to embed the colorful traditional crafts of the rice noodle industry and the technical elements that facilitate the production of rice noodle in automated and intelligent equipment, and provide different equipment and craft services, is still a permanent test problem for equipment manufacturing.

We know that the rice noodle industry is a traditional industry in which small and medium-sized enterprises account for more than 95%. It is an industry that has no national or industry standards for the five key technical points of equipment, formula, technology, sterilization, and anti-aging. It is an institution. A closed-loop industry with no courses, no basic research, no talent team, and no willingness to communicate. The technological level of enterprises is highly uneven, and the demand of enterprises for instant rice noodle automation equipment and the four major processes is therefore very urgent.

In our research and development practice in recent years, we have formed an enterprise-school-enterprise-research model through exchanges and learning with dozens of leading rice noodle manufacturers with regional characteristics, forming an industry-university-research platform with Jiangnan University, and Jiangnan University The rice product green technology research center platform of Xiangtan Jubao Jinhao Biology is rooted in the research and manufacture of rice flour automation and intelligent equipment, the research and production of special rice flour, and the basic process research service of rice flour. We are willing to dedicate scientific research results and decades of rice noodle production experience to our customers as part of our rice noodle equipment service.

In our research and development practice in recent years, we have formed an enterprise-school-enterprise-research model through exchanges and learning with dozens of leading rice noodle manufacturers with regional characteristics, forming an industry-university-research platform with Jiangnan University, and Jiangnan University The rice product green technology research center platform of Xiangtan Jubao Jinhao Biology is rooted in the research and manufacture of rice flour automation and intelligent equipment, the research and production of special rice flour, and the basic process research service of rice flour. We are willing to dedicate scientific research results and decades of rice noodle production experience to our customers as part of our rice noodle equipment service.

Our smart manufacturing and future services include the following:

1. Prenatal and postnatal production process training;

2. Formulation process service and agent research training service;

3. Sterilization process and formulation services and research and development services;

4. Anti-aging process and formulation services;

5. Production testing operation training service;

6. On-site production line operation guidance service;

7. Equipment and technology upgrade services;

8. Personalized customization and transformation services of equipment and crafts;

9. Production line and process after-sales service;

10. Integrated project service.

For the sake of users, to create value for users, to serve the rice noodle industry, to make good rice noodle, and to make green rice noodle is our original intention of establishing Haitejia.

We are soberly aware that the future and rise and fall of equipment intelligent manufacturing depend on our future services.

Post time: Dec-08-2022