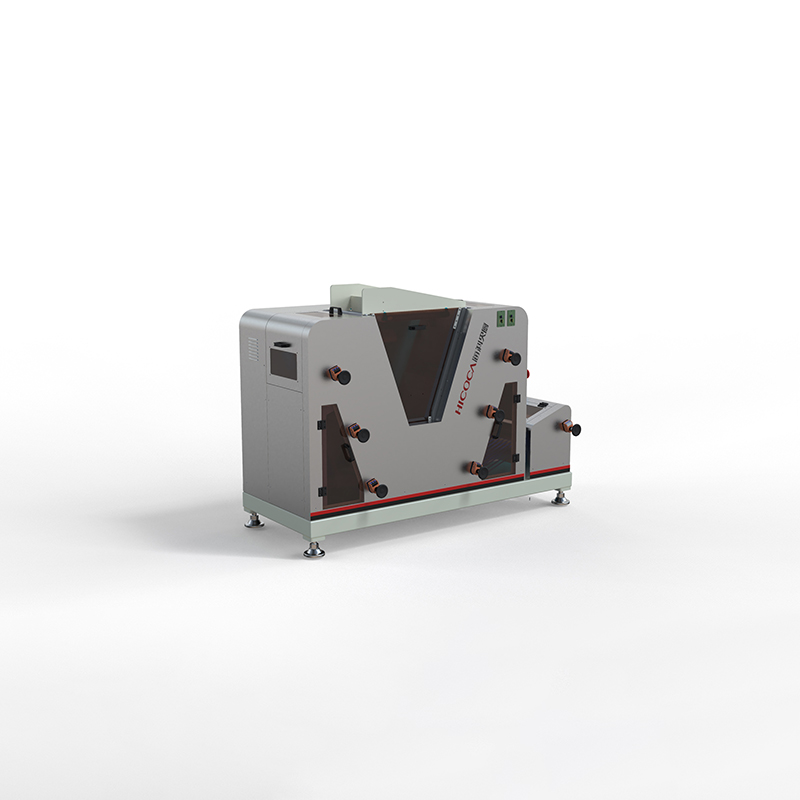

Hot New Products Chewy Noodles Packaging Line - Automatic Carton Erector – Hicoca

Hot New Products Chewy Noodles Packaging Line - Automatic Carton Erector – Hicoca Detail:

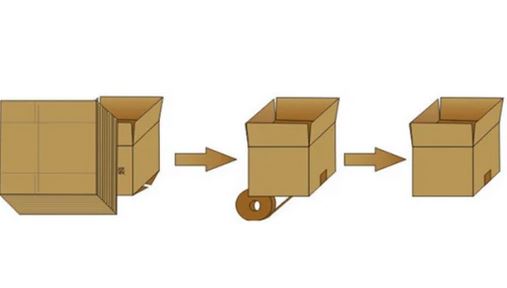

Contains

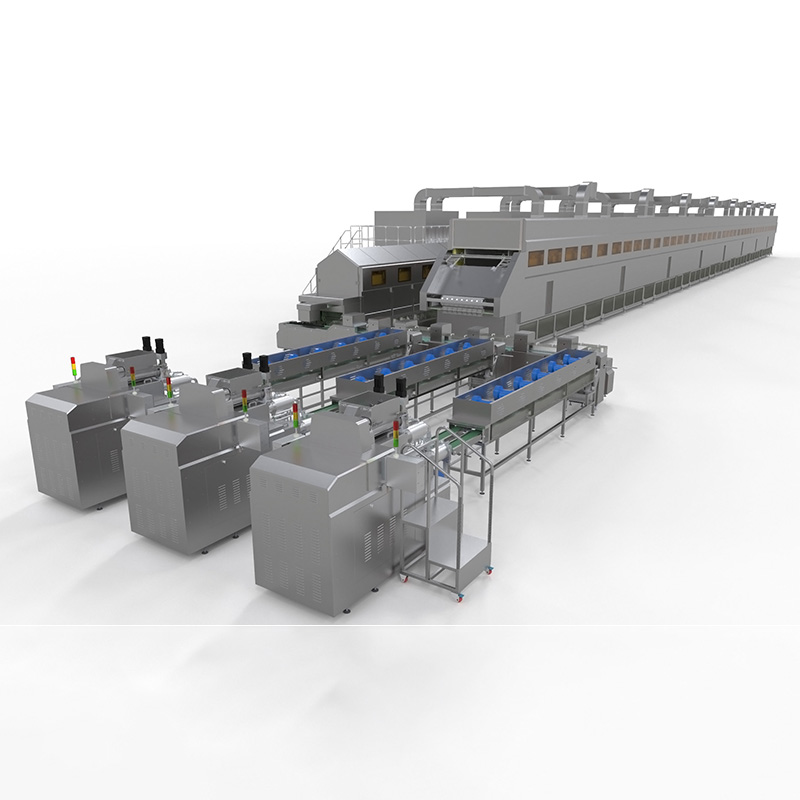

1, automatic pallet library: tray out of the warehouse, transport tray;

2. Steering transplanting device: 90 degree steering transplanting and conveying positioning;

3. Material transportation: the material is transported to the palletizing position;

4, automatic stacking palletizer: palletizing material;

5. Heavy-duty transportation: output and positioning after full load.

Product Highlights:

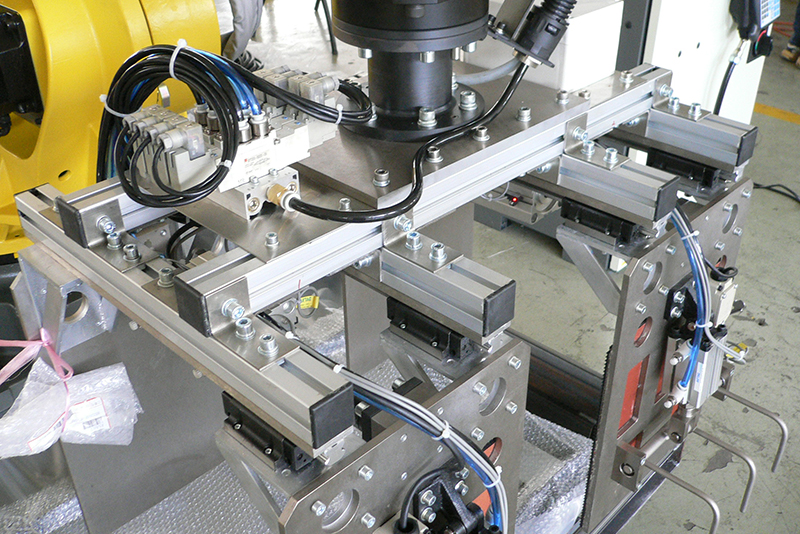

1. Low- or high-position palletizers, robotic palletizers, and depalletizers can be made according to the actual situation of the venue.

2, using touch screen operation to achieve man-machine dialogue, production speed, fault causes and location at a glance;

3. Intelligent control of carton sorting, stacking layer, pallet supply and output, simple operation;

5, large pallet library capacity, can accommodate 8-15 at a time.

Application range

Put corrugated boxes, plastic boxes, barrel-shaped packaging, bag-shaped packaging, turnover baskets, paper bags, etc., which have been loaded into the product, on a pallet according to a certain arrangement, and output them after automatic multi-layer stacking, which is convenient for forklift trucks. Store in the warehouse.

The main technical parameters

| Object: | corrugated boxes, plastic boxes, barrel-shaped packaging, bag-shaped packaging, turnover baskets, paper bags, |

| Power / power: | single channel: 380V; 50Hz ± 10%; 5.5KW

Dual channel: 380V; 50Hz ± 10%; 11KW |

| Palletizing speed (piece / min): | single channel 5-16

Dual channel 5-16 |

| Pallet height (mm): | ≤ 2000 (special requirements can be customized) |

| Pallet size L × W (mm): | (1000-1200) × (1000-1200) (special specifications can be customized) |

| Machine size L*W*H(mm): | Custom |

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" could be the persistent conception of our organization for your long-term to establish alongside one another with shoppers for mutual reciprocity and mutual benefit for Hot New Products Chewy Noodles Packaging Line - Automatic Carton Erector – Hicoca , The product will supply to all over the world, such as: Turkmenistan, Slovakia, United Arab Emirates, Our company is working by the operation principle of "integrity-based, cooperation created, people oriented, win-win cooperation". We hope we can have a friendly relationship with businessman from all over the world

The enterprise has a strong capital and competitive power, product is sufficient, reliable, so we have no worries on cooperating with them.