High reputation Gardenia Noodle Packaging Line - Two Weighers Automatic Noodle Packaging Machine – Hicoca

High reputation Gardenia Noodle Packaging Line - Two Weighers Automatic Noodle Packaging Machine – Hicoca Detail:

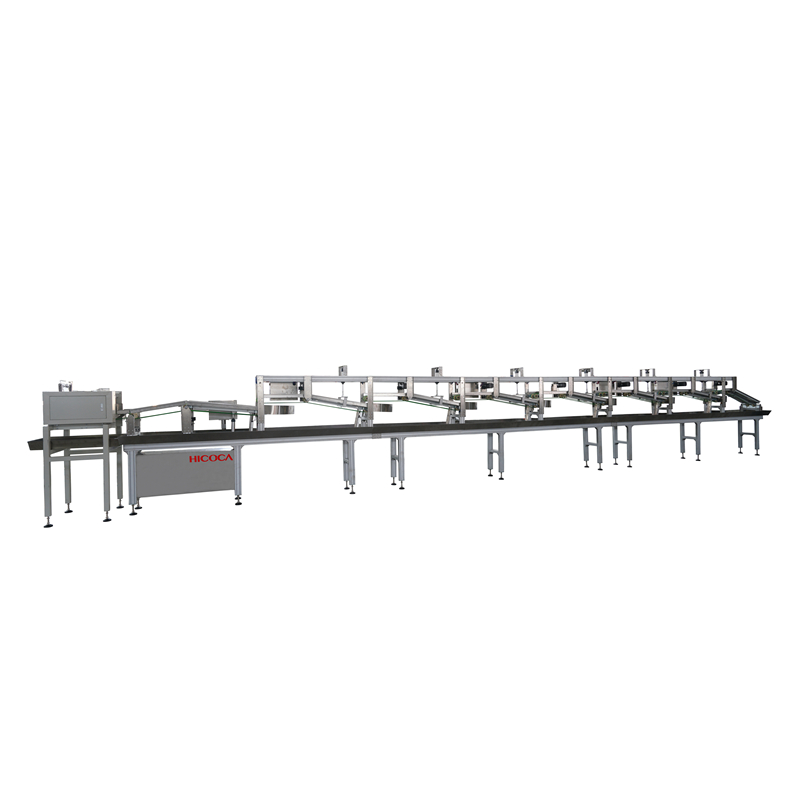

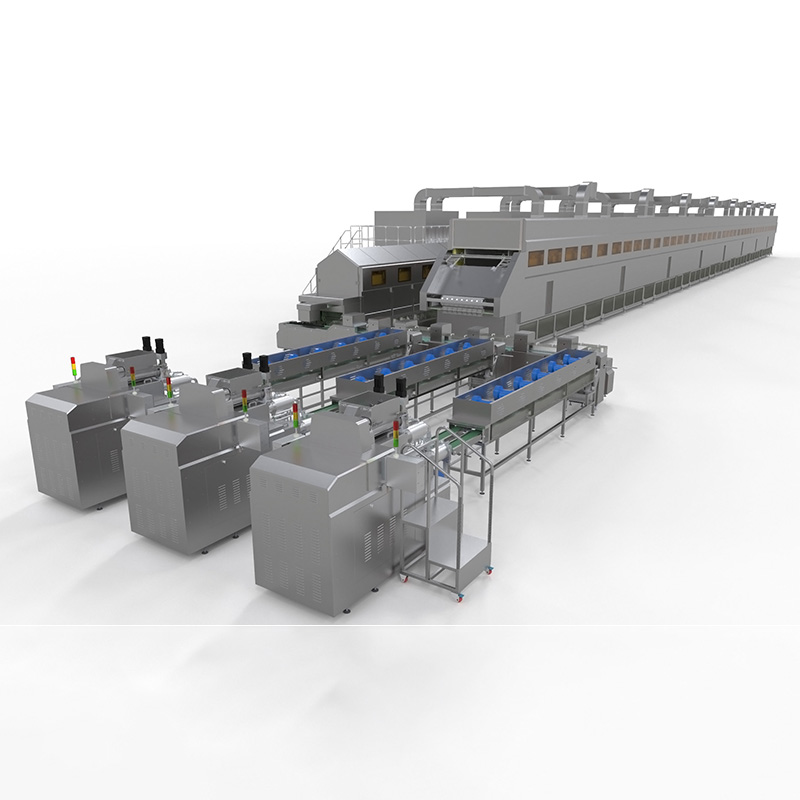

Two Weighers Automatic Noodle Packaging Machine

Application:

It is mainly used for ordinary plastic packaging of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, rice noodles and other long strips of food. The packaging process is completed through automatic weighing, output, packaging into bags.

Technical Specifications:

| Voltage | 220v |

| Frequency | 50-60Hz |

| Power | 6.8 KW |

| Air consumption | 4L/min |

| Machine size | 6050L*3200W*1550H mm |

| Packing range | 200 ~500 ±2.0g; 500~1000 ±3.0g |

| Packing speed | 30-45 bags/min |

Contents:

1. packing machine: one set,

2. conveyor line: one set,

3. weighing machine: two sets,

4. lifting engine: two sets.

Highlights:

1. This is the patented equipment of our factory HICOCA. Round film package facilitates the automation of reorganization, encasement, bagging, storage and transportation of the contents like noodle, spaghetti, etc. In addition, it can protect them from breaking.

2. Packing accuracy is highly enhanced by the high speed motion controller and high precision servo driving system. It’s stable and durable.

3. It can be operated by one person only and greatly reduces the labor and packaging costs. The daily capacity is 36-48 tons.

4. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

Working conditions:

1. Site requirements: flat floor, no shaking or bumping.

2. Floor requirements: hard and non-conductive.

3. Temperature: -5~40ºC

4. Relative humidity: <75%RH, no condensation.

5. Dust: no conductive dust.

6. Air: no flammable and combustible gas or objects, no gas, which can make damage to mental.

7. Altitude: under 1000 meters

8. Ground connection: safe and reliable ground environment.

9. Power grid: stable power supplying, and volatility within +/-10%.

10. Other requirements: keep away from rodents

Product detail pictures:

Related Product Guide:

Our mission should be to turn out to be an innovative supplier of high-tech digital and communication devices by furnishing benefit added design and style, world-class manufacturing, and repair capabilities for High reputation Gardenia Noodle Packaging Line - Two Weighers Automatic Noodle Packaging Machine – Hicoca , The product will supply to all over the world, such as: Madrid, Canberra, Greece, During in 11 years, We have participated in more than 20 exhibitions, obtains the highest praise from each customer. Our company has been devoting that "customer first" and committed to helping customers expand their business, so that they become the Big Boss !

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.