Good Wholesale Vendors Mueller Noodles Packing Line - Automatic 3D M-Shape Bag Noodle Packaging Machine – Hicoca

Good Wholesale Vendors Mueller Noodles Packing Line - Automatic 3D M-Shape Bag Noodle Packaging Machine – Hicoca Detail:

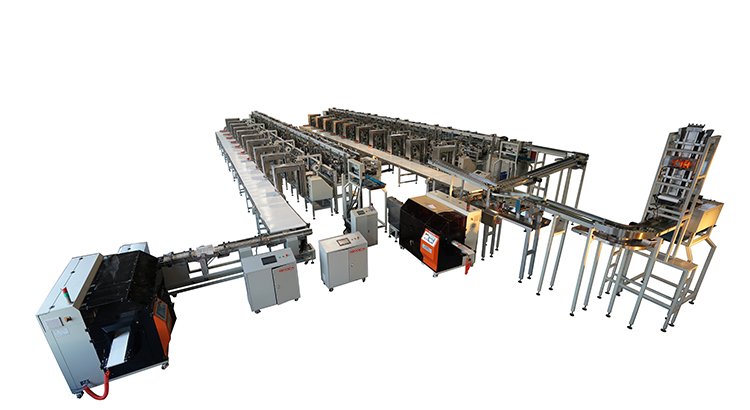

Automatic 3D M-Shape Bag Noodle Packaging Machine

1. With Omron PLC and touch screen

2. With Magic Eyes tracing

3. With Servo motors controlling

Content:

M-shape bags packing machine 1 set,

conveyor line 1 set,

weighing machine 3 sets,(1 to 4 sets can be chosen according to your request.)

lifting engine 3 sets,

pneumatic linking bucket 3 sets

Specs:

| Object | noodle, Spaghetti, pasta,rice noodle | |

| length of the noodle |

|

|

| thickness | 0.6~1.4mm | |

| width of the noodle | 0.8~3.0mm | |

| packing rate | 30~55bags / min | |

| weight range | 200~500g 200~1000g | |

| Inputting method | number input | |

| variable setting | 0.1g | |

| exact value | 400~1000g, ± 3.0g, percent of pass ≥ 96% | |

| size | 6050mm× 3200mm× 1650mm | |

| voltage | AC220v/50-60Hz/7000W |

Application:

This equipment is suitable for M-shaped three-dimensional bag forming and packaging of 180~260mm long bulk noodle, spaghetti, pasta, rice noodle and other materials. Automatic weighing, bag making, lifting, conveying and other steps to achieve the entire process of automatic three-dimensional bag packaging.

Highlights:

1. Solid forming: As our patented equipment, it realizes the automatic production of top grade three dimensional packaging.

2. Automatic bag making with film achieves different packages varied from 400g to 1000g and reduces costs of labor and film.

3. Reciprocating horizontal sealing makes the sealing dog-ears beautiful.

4. Electrical anti-cutting avoids injury to staff and equipments

5. Function of empty bags detection can prevent empty bags effectively and save the cost of film.

6. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

Product detail pictures:

Related Product Guide:

The corporation upholds the philosophy of "Be No.1 in excellent, be rooted on credit rating and trustworthiness for growth", will proceed to provide aged and new buyers from home and abroad whole-heatedly for Good Wholesale Vendors Mueller Noodles Packing Line - Automatic 3D M-Shape Bag Noodle Packaging Machine – Hicoca , The product will supply to all over the world, such as: San Diego, Norway, Bhutan, Our products and solutions are sold to the Middle East, Southeast Asia, Africa, Europe, America and other regions, and are favorably appraised by clients. To benefit from our strong OEM/ODM capabilities and considerate services, be sure to contact us today. We will sincerely create and share success with all clients.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.