Good User Reputation for Noodles Banane Wala Machine - Full-automatic fresh rice noodle production line – Hicoca

Good User Reputation for Noodles Banane Wala Machine - Full-automatic fresh rice noodle production line – Hicoca Detail:

Product introduction

Using rice as the main raw material, it produces fresh wet rice noodles with a moisture content of 66% to 70%. It is packaged in a composite film bag and can be stored for 6 months after preservation.

Technological Process

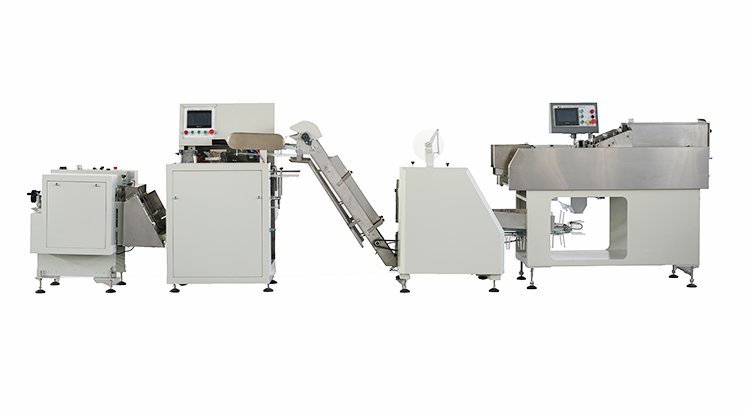

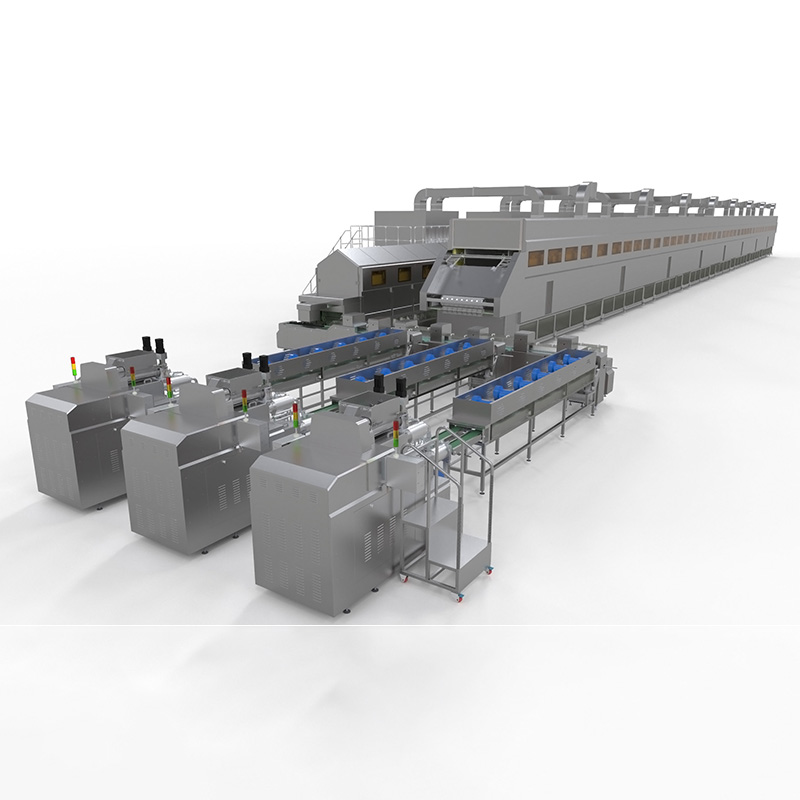

Mixing rice → micro-fermented soaked rice → filtering water → crushing rice → mixing flour → automatic feeding → maturing and extruding wire → cutting off fixed strip → checking weight → conveying → automatic boxing → aging → softening →

Shaping→sterilization→automatic unloading→bag packing→sterilization→finished product.

Machine Highlights

The production specifications are 200-240g/bag, 4320 bags/h, and the production capacity is 0.86-1.04 tons/hour. 10 hours per shift, 9 hours for silk production, 15 employees per shift, 18.7T fresh wet powder for two shifts.

Technical Parameters

| Rated voltage | 380V |

| Water consumption | 8 tons/ton powder |

| Electricity consumption | 400 degrees/ton powder |

| Air consumption | 2.6 tons/ton powder |

Product detail pictures:

Related Product Guide:

We rely upon strategic thinking, constant modernisation in all segments, technological advances and of course upon our employees that directly participate in our success for Good User Reputation for Noodles Banane Wala Machine - Full-automatic fresh rice noodle production line – Hicoca , The product will supply to all over the world, such as: Miami, Guinea, Sudan, Most problems between suppliers and clients are due to poor communication. Culturally, suppliers can be reluctant to question items they do not understand. We break down people barriers to ensure you get what you want to the level you expect, when you want it. Faster delivery time and the product you want is our Criterion .

The manufacturer gave us a big discount under the premise of ensuring the quality of products, thank you very much, we will select this company again.

Write your message here and send it to us