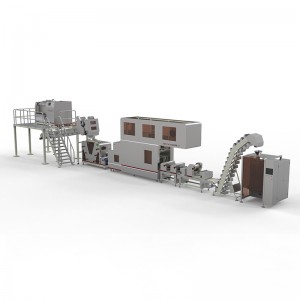

Fully Automatic Straight Fresh Wet Rice Noodle production line

Product Overview

1.The PLC intelligent rice mixing system fundamentally solves the problem of accurate formula.

2.The PLC intelligent control of the front-end rice washing, soaking, crushing, and powder mixing system reduces labor intensity, and quantitative control improves moisture accuracy.

3.The finished product of the self-cooking extruder can reach more than 83% cooked, and the extrusion thickness and speed are uniform.

Equipment parameters

|

Capacity |

Labor |

Water consumption |

Electric consumption |

Air consumption |

|

520 kg/hour *2 set = 1040 kg/hour |

11~12 staffs from rice supply to packaging |

8 tons/ton rice noodle |

400kw*h/ton rice noodle |

2.1~2.3 ton/ton rice noodle |

Product Layout

Technological process

Rice supply

Microfermentation soaking

Draining

Rice crushing

Powder mixing

Automatic feeding

Aging

Automatically loading in box

Conveying

Weighing

Cutting and shaping

Cooking and extruding

Steaming

Aging

Softening

Softening

Sterilizing

Automatically unloding

Finished products

Sterilizing

Packaging

Service content

01

Production process training

02

Formula process services

03

Sterilization process and R&D services

04

Anti-aging process and formulation services

05

Production testing operation training service

06

On-site production line operation guidance service

07

Equipment and process technology upgrade services

08

Equipment and process customization and transformation services

09

Production line, process after-sales service

10

Integrated project services

Introduction to Core Equipment

Rice pre-processing system (milling)

The intelligent control rice mixing system fundamentally solves the problem of accurate formula

PLC intelligently controls the front-end rice washing, soaking, crushing, and powder mixing systems, and quantitative control improves moisture accuracy.

Rice noodle extruding machine

Using double-cylinder maturation and single-cylinder extrusion mode, the hourly production capacity can reach 400kg

High extrusion efficiency and good strip stability

Using split screw roller mode, the cylinder and screw roller are easy to clean

Spreading machine

Cutting and hanging rod machine

The automatic cutting and hanging rod machine for rice vermicelli has high production efficiency and low loss, and realizes continuous production of rice vermicelli. After the rice vermicelli is cut and formed, it is quickly hung on the rod and enters the next process.

Traditional Aging box

Advanced technology, reasonable equipment structure, beautiful appearance, large production capacity, stable product quality, intelligent control, easy operation and low labor intensity.