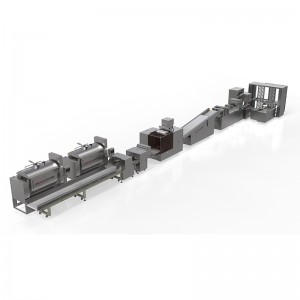

Fully Automatic Snail Rice Noodle production line

Product Overview

1.The PLC intelligent rice mixing system fundamentally solves the problem of accurate formula.

2.The PLC intelligent control of the front-end rice washing, soaking, crushing, and powder mixing system reduces labor intensity, and quantitative control improves moisture accuracy.

3.Double extrusion and double box design increase the production capacity to 800kg/h; the cutting uniformity is completely consistent.

Equipment parameters

|

Capacity |

Labor |

Water consumption |

Electric consumption |

Air consumption |

|

400 kg/hour *2 set = 800 kg/hour |

5~6 staffs from rice supply to Drying room |

1.5 tons/ton rice noodle |

320kw*h/ton rice noodle |

1.3~1.5 ton/ton rice noodle |

Product Layout

Technological process

Rice supply

Soaking

Washing Draining

Powder Grinding and storage

Mixing, conveying and feeding

Automatic rubbing

Steaming and aging

Forming and aging

Hanging rod, spreading and cutting

Extruding

Organizing

Automatic Drying

Automatic unloading rod and cutting

Sterilizing

Automatically unloding

Service content

01

Production process training

02

Formula process services

03

Sterilization process and R&D services

04

Anti-aging process and formulation services

05

Production testing operation training service

06

On-site production line operation guidance service

07

Equipment and process technology upgrade services

08

Equipment and process customization and transformation services

09

Production line, process after-sales service

10

Integrated project services

Introduction to Core Equipment

Rice pre-processing system (milling)

The intelligent control rice mixing system fundamentally solves the problem of accurate formula

PLC intelligently controls the front-end rice washing, soaking, crushing, and powder mixing systems, and quantitative control improves moisture accuracy..

Rice noodle extruding machine

1.Adopting double-drum maturation and single-drum extrusion mode, the hourly production capacity can reach 400kg

2.High extrusion efficiency and good strip stability

3.Adopting split screw roller mode, the cylinder and screw roller are easy to clean