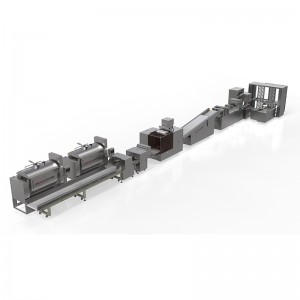

Fully automatic ramen noodle production line

Product Overview

Advantages of hand-rolled noodle production line:

1.High production capacity, with an average of 25kg of finished noodles produced per person per hour, which is 4-6 times that of other production forms;

2.The use of a rotary rolling bionic dough kneading machine dedicated to Japanese hand-extended noodles makes the dough more evenly kneaded and the formed gluten more resilient;

3.Original gradual shrinkage calendering production process, continuous automated production, stable operation and high production efficiency;

4.The rough and fine ramen machines use artificial rotation and ramen pulling technology to give the noodles the taste of traditional handmade noodles.

Equipment parameters

|

Capacity |

Air supply |

Rated power |

|

10-30 tons/day |

0.6~0.7Mpa |

200KW |

Product Layout

Technological process

Dough mixing, dough aging

Taper Calendering, slitting

Dough rolling and aging in a basin

Rough pulling then rolling and aging in a basin

Cutting , packaging

Stretching , drying

Step noodle lifting, aging

Fine pulling, rod loading, aging

Product feature

More resilient

More bouncy

Hollow

Boiling resistance

Won’t stick easily

Introduction to Core Equipment

Rotary rolling bionic intelligent dough mixer

•Model: MHMX 150

•Applied range: For dough mixing of Steamed bread, steamed stuffed bun, Bread, Ramen

•Feature: Imitation hand rolling dough mixing makes dough aging faster and have a more uniform texture.The inner cavity structure of the dough mixing pot is simple, making it safer and easier to clean. Fully automatic raw material mixing and one-touch convenient operation.

•Main parameters: Rated voltage: 380V

Rated power: 9KW

Air supply: 0.4-0.6MPa

Demension: 1760*910*1750mm

Taper calender forming machine

•Model: MJSYM/30

•Applied range: Suitable for dough pressing, narrowing and cutting continuously of Hand-extended noodle and ramen.

•Feature:The wide dough strip can be continuously thinned and narrowed according to the output and product requirements, and the output dough strip has a consistent width and uniform thickness. According to the needs, the strips are cut into different specifications, the strips are cut evenly, and the end faces are smooth.Multi-node precise monitoring, servo and frequency conversion combined control, to achieve full synchronization of the production line strips, smooth production without accumulation and material breakage. While improving the degree of automation, production efficiency and production stability are also improved simultaneously.

•Main parameters: Rated voltage: 380V

Rated power: 3.8KW

Output thickness:20-30mm

Number calendering: 4 times

Dimension: 4800*730*1400mm

Double station rolling basin machine

•Model: MLMPP/2

•Applied range: Suitable for collecting and aging of dough strip

•Feature: The dough strip is rolled tightly in the basin, which is better for dough aging to improve the texture and taste of the ramen. High degree of automation, efficiently rolling dough strip in the basin without manual intervention.

•Main parameters: Rated voltage: 220V

Rated power: 1.7kw

Dimension: 1620*1330*1120,,

Rod winding machine

•Model:MLMRG O/80

•Applied range: Suitable for moderately stretching the dough strip while winding the dough strip on the rod after fine pulling process.

•Feature: High winding speed and keeping same gap, wide range of applications. The winding of the dough strip with different thickness can be realized by adjusting equipment running parameters. It supports double dough strip winding at the same time for productivity improvement. Double station winding and alternately winding improved productivity. Smooth winding process, uniform stress on dough strip, good stretching effect, fully maintaining the internal stringiness of Ramen.

•Main parameters: Rated voltage: 380V

Rated power: 0.5KW

Input thickness: 4-12mm

Widing Speed : 23S/rod

Dimension : 1300*1200*1000mm

Stepping noodle lifting machine

•Model : MLMTM/800

•Applied Range: Suitable for noodle step stretching after dough winding and aging.

•Feature : According to the technology of stringiness, the ramen is step stretched. Realized Ramen gradually extending, without ruining stringiness of ramen. Smooth stretching process, uniform stress on ramen, good stretching effect. Multiple groups of ramen simultaneously alternate stretching, high effient, productivity improvement. Multi-stage step stretching keeps the stringiness of the ramen, making the noodles more resilient.

•Main parameters: Rated voltage : 380V

Rated power : 0.4KW

Efficiency : 600kg/h

Numbers of stretching: 7 times

Dimentsion: 2500*1300*2000mm

Manual noodle cutting machine

•The cut surface is neat, no broken noodle, the equipment is durable, and the use of hand-extended noodle cutting machine can greatly improve product efficiency.

Intelligent energy-saving drying system

Process characteristics

Flexible Drive

Energy Saving

PLC control

Regional division

Airflow control

Temperature and humidity control

Technical Description

Hot air centralized processing system

•The partition scheme strictly follows the dehydration law of noodles and sets up partitions that are independent of each other. Each partition is set as an independent operating unit.

•The airflow control scheme starts with the overall design of the workshop, where each drying zone is equipped with air replenishment and moisture removal functions. The air volume is adjusted separately through the air distribution system to achieve the adjustment of positive and negative pressure between each drying zone, ensuring uniform temperature and humidity along the length direction of each drying chamber.

•The air to air heat exchanger installed in the intake and exhaust units performs primary recovery of waste heat from tidal discharge, using technical solutions such as staged recovery, air circulation, and zone heating to achieve ultimate heat recovery and excellent energy-saving effects.

Adjustable speed noodle conveyor system

•The speed regulating noodle conveyor device has adjustable noodle rod movement speed, spacing, and drying time for each drying step, fully adapting to flexible noodle production.

Intelligent control system

The intelligent automatic control system realizes unmanned management of the drying room, with a human-machine interactive touch screen operation interface, and remote monitoring can be added according to user needs.

Our energy-saving drying system can reduce costs by more than 60% compared with traditional drying methods, reducing emissions and contributing to environmental protection.

60%+

Product Details