Featured

-

Hot-selling Producing Equipment - Automatic Shrink Film Sealing Instant Noodle Packing Machine – Hicoca

Scope of application In the process of making noodles such as fresh wet noodles and semi-dry noodles, multi-layer composite rolling of noodles and noodles is realized Product Highlights 1. The product adopts 7 pairs of high chromium alloy rollers and 7 three-phase frequency conversion motors independently controlled, and the pressing effect is excellent. 2. The overall V-shaped layout is convenient for sanitary cleaning. 3. Continuous and automatic operation to achieve a six-layer c... -

Cheap price Low Cal Noodles Packaging Line - Carton packing machine – Hicoca

Advantages 1,complete modular design to be convenient layout based on actual usage of customer’s site. 2, all electrical control components and PLC are used by international famous brand to ensure the accurate and stable operations as well as the package quality. 3,The unique box positioning system can be ensure box successfully entered the preset stations for the packing stability. Work object Food Carton packaging Packing range 200g-1000g Packing capacity 120-150 bags/min Volt... -

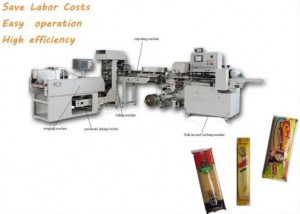

2021 wholesale price Uni Noodles Packaging Line - Stick Noodle Papered wrapping and Packing Machine – Hicoca

Contains 1,weighting machine: one set 2, double-slat bundling machine: one set 3, paper wraping: one set Applications: automatically finish the process of weighting, outputting, filling and double-slat packing of the Spaghetti and other noodle Highlights Packing range is much larger than the earlier model. Package is with high density which is suitable to long-distance transportation. Packing speed is 4-6 times than manual packing. Reduce the labor intensity. Intelligent acceleratio... -

Factory selling Slim Noodle Packaging Equipment - High Speed Automatic Aligning Pillow Bag Packing Machine – Hicoca

High Speed Automatic Aligning Pillow Bag Packing Machine Application: It is suitable for packaging chocolate, wafer, puff, bread, cake, candy, medicine, soap, etc. Technical Specification: Object dimension(L x W x H) (55-185mm)x(5-30mm)x(15-60mm) Packing speed 350 bags/min Equipment dimension 9600mmx1200mmx1750mm Voltage AC220V 50~60Hz Power 9.6kW Highlights: 1. The design of film feeding mechanism can automatically connect the film, change film automatically without shu... -

-

Factory best selling Grey Noodles Packaging Equipment - Automatic Heat Shrink Wrapping Machine – Hicoca

Automatic Heat Shrink Wrapping Machine Main specifications: Voltage AC 220v Frequency 50~60Hz Power 24.5KW Air Cosumption 6L/min Packaging material PE, POF Coil film Sealing knife temperature 180~300ºC Packing speed 80 ~100 bags/min Packaging range (80~500)L×(30~120)W×(10~120)H mm Equipment size 9000L×1190W×1650H mm Application: This machine is suitable for automatic packaging of instant noodle, rice noodle, dried noodle, biscuit, snack, ice cream, tissue, drinks, hardw... -

factory low price Hollow Noodles Packing Equipment - Full automatic palletizer – Hicoca

Applications automatically finish the process of carton opening , packed noodle bag filling, carton sealing with tape. Advantages 1,complete modular design to be convenient layout based on actual usage of customer’s site. 2, all electrical control components and PLC are used by international famous brand to ensure the accurate and stable operations as well as the package quality. 3,The unique box positioning system can be ensure box successfully entered the preset stations for the packing sta... -

Good Quality Producing Line - Fresh noodle producing machine – Hicoca

Scope of application Automatic production of dough sheet and dough flocculation multi-layer composite fresh wet noodle. Process flow Automatic powder supply-automatic salt water mixing, water supply-kneading-noodle floc maturation-flake composite calendering-noodle mat maturation-continuous calendering-strip forming-packaging Product Highlights 1. New noodle making technology The original noodle belt and noodle flocs are compounded and continuously calendered, and the noodle fl... -

Hot New Products Chewy Noodles Packaging Line - Automatic Noodle Packing Machine with Three Weighers – Hicoca

Automatic Noodle Packing Machine with Three Weighers Contents: 1. packing machine: one set, 2. conveyor line: one set, 3. weighing machine: three sets, 4. lifting engine: three sets, 5. pneumatic linking bucket: three sets Application: It is mainly used for packing of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The packing process is completed through automatic weighing, output, filling and sealing. Hig... -

High Quality Yi Mian Noodles Packing Equipment - Automatic Pasta Spaghetti Noodle Weighing Packing Machine with One Weigher – Hicoca

Automatic Pasta Spaghetti Noodle Weighing Packing Machine with One Weigher Contents: 1. packing machine: One set, 2. conveyor line: One set(1m), 3. weighing machine: One set, 4. lifting engine: One set , 5. pneumatic linking bucket:One set Application: It is mainly used for wrapping of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The wrapping process is completed through automatic weighing, output, filling... -

Hot sale Nooodle Wrapping Machine - Carton packing machine – Hicoca

Advantages 1,complete modular design to be convenient layout based on actual usage of customer’s site. 2, all electrical control components and PLC are used by international famous brand to ensure the accurate and stable operations as well as the package quality. 3,The unique box positioning system can be ensure box successfully entered the preset stations for the packing stability. Work object Food Carton packaging Packing range 200g-1000g Packing capacity 120-150 bags/min Volt... -

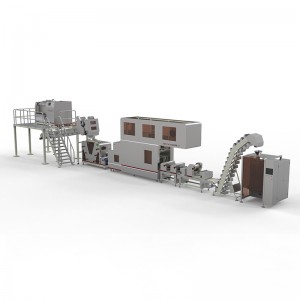

Hot sale Factory Auto Noodle Maker - Automatic Rice Macaroni Production Line – Hicoca

Automatic Rice Macaroni Production Line Model: QZDTXMF-650 With rice as the main raw material, the water content of the rice macaroni is 14-15%, and the shelf life can reach 18 months.Production Process: rice feeding→soaking→rinsing→rice grinding→mixing & conveying & feeding→extruding→cutting→cooling & conveying→shaping & aging→steaming→secondary aging→loosening→drying→end product Highlights: 1. Product specification: 4mm, 6mm and 8mm. The production capacity is 750kg / h. 2. ...