Featured

-

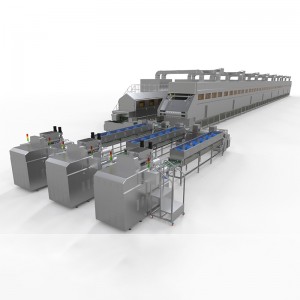

Discountable price Electric Ramen Noodle Maker - Intelligent Straight Rice Noodle Making Machine Production Line – Hicoca

Intelligent Straight Rice Noodle Making Machine Production LineModel: QZDZTMF-750With rice as the main raw material, the water content of the straight rice noodle is 14-15%, and the shelf life can reach 18 months. Production Process: rice feeding→soaking→rinsing→rice grinding→mixing & conveying & feeding→extruding→hanging & separating & cutting→shaping & aging→steaming→secondary aging→loosening→rods arranging→drying→cutting→weighing→packaging Highlights: 1. Product specifi... -

Factory Cheap Hot Flour Noodles Asian Packaging Line - Automatic Pouch Dispenser machines – Hicoca

Features The Automatic Pouch Dispenser can cut pouches in row one by one (or cut by couples as you like), and dispense them onto the conveyer accurately. It can also follow the conveyer’s speed automatically, so as to dispense pouch onto the right place no matter how the speed changes. Standard Features (1) High efficiency: Automatically pouch feeding, cutting and dispensing; (2) Health: Machine dispensing avoiding manual touching; (3) High Adjustability: Suitable pouches of varied... -

Wholesale Price Best Spaghetti Maker - Full-automatic fresh rice noodle production line – Hicoca

Product introduction Using rice as the main raw material, it produces fresh wet rice noodles with a moisture content of 66% to 70%. It is packaged in a composite film bag and can be stored for 6 months after preservation. Technological Process Mixing rice → micro-fermented soaked rice → filtering water → crushing rice → mixing flour → automatic feeding → maturing and extruding wire → cutting off fixed strip → checking weight → conveying → automatic boxing → aging → softening → Shapi... -

Best Price for Heat Shrink Packaging Machinery - Automatic Shrink Film Sealing Instant Noodle Packing Machine – Hicoca

Scope of application In the process of making noodles such as fresh wet noodles and semi-dry noodles, multi-layer composite rolling of noodles and noodles is realized Product Highlights 1. The product adopts 7 pairs of high chromium alloy rollers and 7 three-phase frequency conversion motors independently controlled, and the pressing effect is excellent. 2. The overall V-shaped layout is convenient for sanitary cleaning. 3. Continuous and automatic operation to achieve a six-layer c... -

Reasonable price Fried Noodle Producing Machine - Stick Noodle Feeding System – Hicoca

Technical specification Voltage: AC220V Frequency: 50Hz Power: 0.16 kw (single scale) Gas consuming: 1L/min (single scale) Equipment size: customized Applied filed This equipment can meet the requirements of carrying spindly products like noodles, pasta, spaghetti, rice noodle’s inside plant. And can be co-used with packaging line. Highlights Equipment can be designed to suit customer’s requirements and workplace layout. The equipment can meet omnidirectional requirements bu... -

Factory Cheap Hot Flour Noodles Asian Packaging Line - Intelligent feeding system – Hicoca

Technical specification Voltage: AC220V Frequency: 50Hz Power: 0.16 kw (single scale) Gas consuming: 1L/min (single scale) Equipment size: customized Highlights Equipment can be designed to suit customer’s requirements and workplace layout. The equipment can meet omnidirectional requirements but with simple design. Stable and automatic internal logistic Operation environment Site requirements: The equipment should be established inside the room with flat floor. No shaking and b... -

Special Design for Flat Noodles Packaging Line - Check weigher – Hicoca

Product introduction This series check weigher is a kind of high speed and high precision online weight inspecting equipment, it’s mainly used for various automatic assembly line and logistical conveyor system to check low or high weight deviation of the on-line products, then, to sort them. And it works with all kinds of packaging production line and conveying system. It’s applied to online detection of pharmaceutical, food, toys, hard-ware, chemical industry. Features ... -

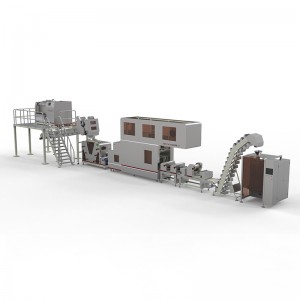

Factory Supply Processing Equipment - Weighing and packing machine – Hicoca

Introduction ·Contains: 1, bulk noodle packing machine: one set, 2, conveyor line: one set, 3, weighting machine: three set, 4,lifting engine (elevator):three set, Application : automatically finish the process of weighting, outputting, filling and sealed packing of the Spaghetti and noodle Object: noodle, Spaghetti length of the noodle 200g~500g:(180~260mm)±5.0mm;500g~1000g:(240~260mm)±5.0mm thickness of the noodle 0.6~1.4mm width of the noodle 0.8~3.0mm packin... -

Fast delivery Noodles Banane Wali Machine - Fresh noodle producing machine – Hicoca

Scope of application Automatic production of dough sheet and dough flocculation multi-layer composite fresh wet noodle. Process flow Automatic powder supply-automatic salt water mixing, water supply-kneading-noodle floc maturation-flake composite calendering-noodle mat maturation-continuous calendering-strip forming-packaging Product Highlights 1. New noodle making technology The original noodle belt and noodle flocs are compounded and continuously calendered, and the noodle fl... -

Wholesale Dealers of Tapioca Noodle Packaging Equipment - High Speed Automatic Aligning Pillow Bag Packing Machine – Hicoca

High Speed Automatic Aligning Pillow Bag Packing Machine Application: It is suitable for packaging chocolate, wafer, puff, bread, cake, candy, medicine, soap, etc. Technical Specification: Object dimension(L x W x H) (55-185mm)x(5-30mm)x(15-60mm) Packing speed 350 bags/min Equipment dimension 9600mmx1200mmx1750mm Voltage AC220V 50~60Hz Power 9.6kW Highlights: 1. The design of film feeding mechanism can automatically connect the film, change film automatically without shu... -

100% Original Ac 220v Home Stainless Electric Automatic Pasta Machine Noodle Pasta Maker Chopped Noodles Maker Machine Pressing Machine 220v - Carton packing machine – Hicoca

Advantages 1,complete modular design to be convenient layout based on actual usage of customer’s site. 2, all electrical control components and PLC are used by international famous brand to ensure the accurate and stable operations as well as the package quality. 3,The unique box positioning system can be ensure box successfully entered the preset stations for the packing stability. Work object Food Carton packaging Packing range 200g-1000g Packing capacity 120-150 bags/min Volt... -