Featured

-

2021 Good Quality Rice Noodle Packing Line - Metal detector – Hicoca

Applications Metal detector can be used in the industry of food, medicine, toy, chemical and leather etc, to detect and remove the iron grain, needle, lead, copper, aluminum and stainless steel etc. It can be also associated the ma-chine with automatic product line. Features Advanced technology Using DDS frequency synthesis, DSP digital signal processing, high efficiency power amplifier and other advanced technology, industry technology leader. Super hardware configuration Adopt dou... -

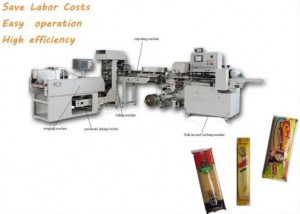

Cheap price Low Cal Noodles Packaging Line - Automatic Noodle Heat Shrink Packing Machine – Hicoca

Automatic Noodle Heat Shrink Packing Machine Application: The machine is suitable for multi-layer superposition shrink wrapping of single bag finished products of long strip materials such as noodles, spaghetti, rice noodles, vermicelli and Yuba. The whole process of shrink wrapping is realized through automatic feeding, aligning, sorting, layered stacking and film covering. Technical Specification: Power 1P 220V /3P 380V 50-60Hz 32KW Weight of each big pack 10~30KG Qty. of bags in ea... -

Chinese wholesale Yin Yong Noodles Packaging Equipment - Automatic 3D M-Shape Bag Noodle Packaging Machine – Hicoca

Automatic 3D M-Shape Bag Noodle Packaging Machine 1. With Omron PLC and touch screen 2. With Magic Eyes tracing 3. With Servo motors controlling Content: M-shape bags packing machine 1 set, conveyor line 1 set, weighing machine 3 sets,(1 to 4 sets can be chosen according to your request.) lifting engine 3 sets, pneumatic linking bucket 3 sets Specs: Object noodle, Spaghetti, pasta,rice noodle length of the noodle 200g~500g(180~260mm)± 5.0mm 500g~1000g(240~260mm)± 5.0mm ... -

Wholesale Discount Noodle Food Packing Equipment - Automatic Pasta Spaghetti Noodle Weighing Packing Machine with One Weigher – Hicoca

Automatic Pasta Spaghetti Noodle Weighing Packing Machine with One Weigher Contents: 1. packing machine: One set, 2. conveyor line: One set(1m), 3. weighing machine: One set, 4. lifting engine: One set , 5. pneumatic linking bucket:One set Application: It is mainly used for wrapping of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The wrapping process is completed through automatic weighing, output, filling... -

Hot New Products Chinese Noodle Packing Line - Automatic Heat Shrink Wrapping Machine – Hicoca

Automatic Heat Shrink Wrapping Machine Main specifications: Voltage AC 220v Frequency 50~60Hz Power 24.5KW Air Cosumption 6L/min Packaging material PE, POF Coil film Sealing knife temperature 180~300ºC Packing speed 80 ~100 bags/min Packaging range (80~500)L×(30~120)W×(10~120)H mm Equipment size 9000L×1190W×1650H mm Application: This machine is suitable for automatic packaging of instant noodle, rice noodle, dried noodle, biscuit, snack, ice cream, tissue, drinks, hardw... -

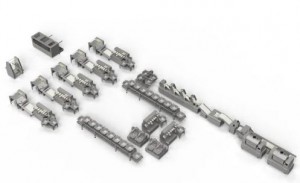

Hot-selling Fresh Noodle Making Machine - Intelligent feeding system – Hicoca

Technical specification Voltage: AC220V Frequency: 50Hz Power: 0.16 kw (single scale) Gas consuming: 1L/min (single scale) Equipment size: customized Highlights Equipment can be designed to suit customer’s requirements and workplace layout. The equipment can meet omnidirectional requirements but with simple design. Stable and automatic internal logistic Operation environment Site requirements: The equipment should be established inside the room with flat floor. No shaking and b... -

-

Europe style for Smart Noodle Packaging Line - High Speed Automatic Aligning Pillow Bag Packing Machine – Hicoca

High Speed Automatic Aligning Pillow Bag Packing Machine Application: It is suitable for packaging chocolate, wafer, puff, bread, cake, candy, medicine, soap, etc. Technical Specification: Object dimension(L x W x H) (55-185mm)x(5-30mm)x(15-60mm) Packing speed 350 bags/min Equipment dimension 9600mmx1200mmx1750mm Voltage AC220V 50~60Hz Power 9.6kW Highlights: 1. The design of film feeding mechanism can automatically connect the film, change film automatically without shu... -

Discount wholesale String Noodles Packaging Equipment - Automatic Shrink Film Sealing Instant Noodle Packing Machine – Hicoca

Scope of application In the process of making noodles such as fresh wet noodles and semi-dry noodles, multi-layer composite rolling of noodles and noodles is realized Product Highlights 1. The product adopts 7 pairs of high chromium alloy rollers and 7 three-phase frequency conversion motors independently controlled, and the pressing effect is excellent. 2. The overall V-shaped layout is convenient for sanitary cleaning. 3. Continuous and automatic operation to achieve a six-layer c... -

Super Purchasing for Mr X Noodle Maker - Automatic Semi Dry Rice Noodle Making Machine Production Line – Hicoca

Automatic Semi Dry Rice Noodle Making Machine Production LineWith rice as the main raw material, the water content of the semi dry rice noodle cake is 42-45%. Packaged in composite film bags, the shelf life after preservation treatment can reach 6 months.Production Process: rice feeding→micro fermented soaking→filtering→rice grinding→mixing→feeding→aging & extruding→cutting & shaping→weight checking→conveying→sorting into boxes→aging→softening→keeping in constant temperature→drainin... -

Wholesale Price China Best Noodle Machine - Automatic Ramen Noodle Making Machine Production Line – Hicoca

Automatic Ramen Noodle Making Machine Production Line Application Automatic production of hand-drawn noodles, hollow noodles, slivers, and hand-extended noodles, etc. Process flow Automatic powder supply-automatic salt water mixing, water supply-kneading-maturing-rolling and opening-pan mat maturing-coarse ramen noodles-pan mat maturing-fine ramen noodles-winding on the rod-maturing-stepping noodles-maturing-ramen forming-baking Dry-cut noodle-pack Product Highlights 1. The degree of automati... -

factory Outlets for Ling Ling Noodles Packaging Equipment - Automatic Carton Erector – Hicoca

Contains 1, automatic pallet library: tray out of the warehouse, transport tray; 2. Steering transplanting device: 90 degree steering transplanting and conveying positioning; 3. Material transportation: the material is transported to the palletizing position; 4, automatic stacking palletizer: palletizing material; 5. Heavy-duty transportation: output and positioning after full load. Product Highlights: 1. Low- or high-position palletizers, robotic palletizers, and depalletizers can be ma...