Factory making Wokka Edamame Noodles Packing Line - Automatic Noodle Packing Machine with Three Weighers – Hicoca

Factory making Wokka Edamame Noodles Packing Line - Automatic Noodle Packing Machine with Three Weighers – Hicoca Detail:

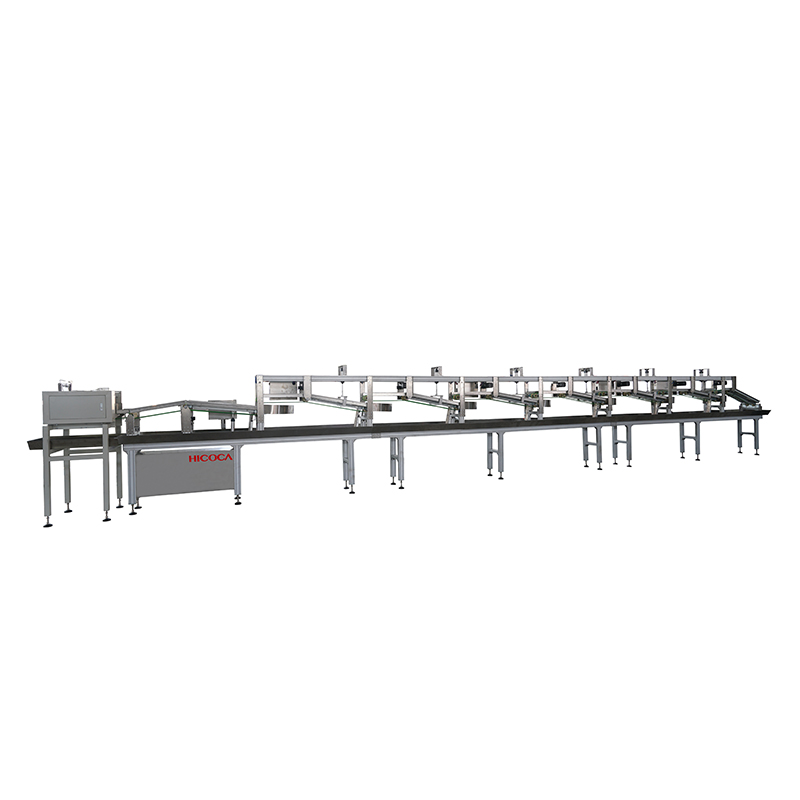

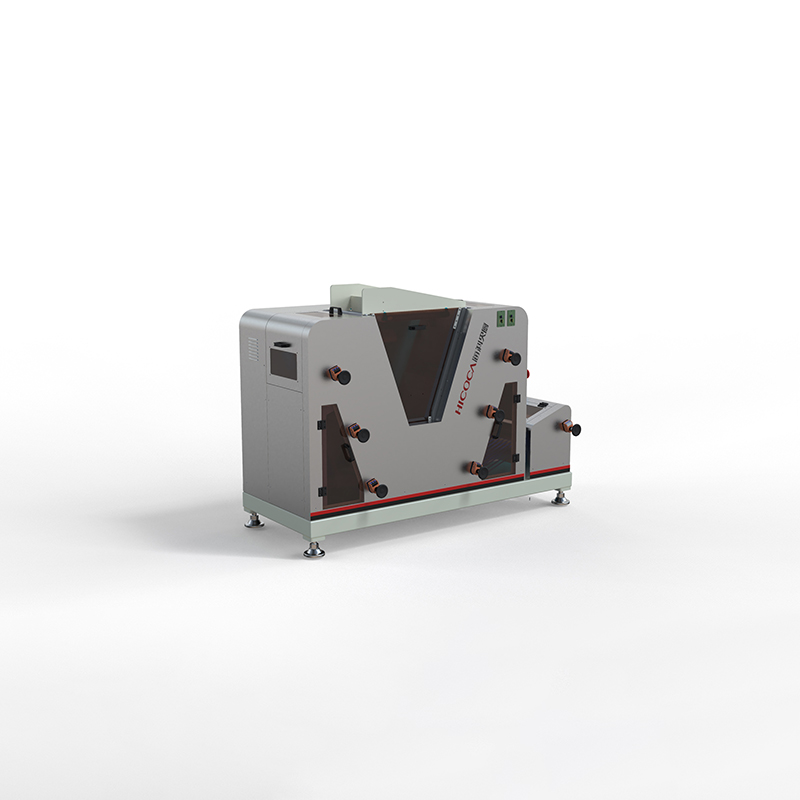

Automatic Noodle Packing Machine with Three Weighers

Contents:

1. packing machine: one set,

2. conveyor line: one set,

3. weighing machine: three sets,

4. lifting engine: three sets,

5. pneumatic linking bucket: three sets

Application:

It is mainly used for packing of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The packing process is completed through automatic weighing, output, filling and sealing.

Highlights:

1. This is the patented equipment of our factory HICOCA. Round film package facilitates the automation of reorganization, encasement, bagging, storage and transportation of the contents like noodle, spaghetti, etc. In addition, it can protect them from breaking.

2. Packing accuracy is highly enhanced by the high speed motion controller and high precision servo driving system. It’s stable and durable.

3. It can be operated by one person only and greatly reduces the labor and packaging costs. The daily capacity is 36-48 tons.

4. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

Technical Specification:

| Object: | Spaghetti, Long Pasta, Noodle, rice noodle |

| Length of the spaghetti | 100g~500g:(180~260mm)±5.0mm;500g~1000g:(240~260mm) |

| Thickness of the spaghetti | 0.6~1.4mm |

| Width of the spaghetti | 0.8~3.0mm |

| Packing rate | 30~60/min |

| Weight range | 100~1000g |

| Inputting method | Number input |

| Tolerance | 100~500g ,±2.0g-96%; 500~1000g,±3.0g-96%; |

| Dimensions | 6700mm×3400mm×1650mm |

| Voltage | AC220v/50HZ/9KW |

Product detail pictures:

Related Product Guide:

We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients for Factory making Wokka Edamame Noodles Packing Line - Automatic Noodle Packing Machine with Three Weighers – Hicoca , The product will supply to all over the world, such as: Australia, Turkmenistan, New Delhi, Today, We are with great passion and sincerity to further fulfill our global customers' needs with good quality and design innovation. We fully welcome customers from all over the world to establish stable and mutually beneficial business relationships, to have a bright future together.

The supplier cooperation attitude is very good, encountered various problems, always willing to cooperate with us, to us as the real God.