Factory For Fettuccine Maker - Automatic Semi Dry Rice Noodle Making Machine Production Line – Hicoca

Factory For Fettuccine Maker - Automatic Semi Dry Rice Noodle Making Machine Production Line – Hicoca Detail:

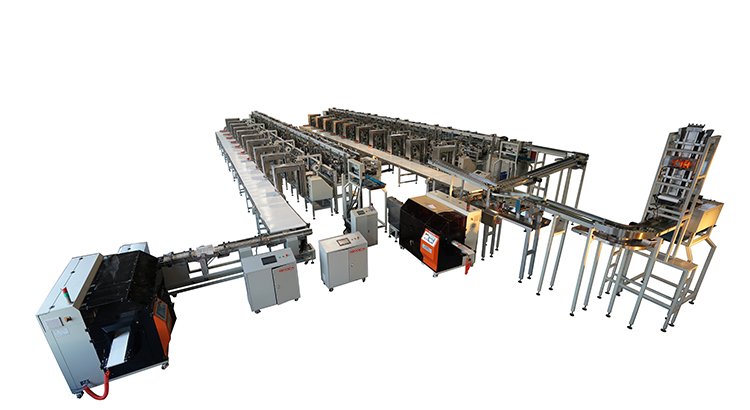

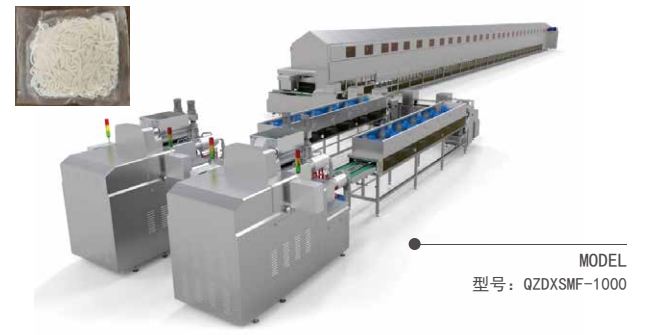

rice feeding→micro fermented soaking→filtering→rice grinding→mixing→feeding→aging & extruding→cutting & shaping→weight checking→conveying→sorting into boxes→aging→softening→keeping in constant temperature→draining→sterilizing→box unloading→bag packing→sterilizing→end product

Highlights:

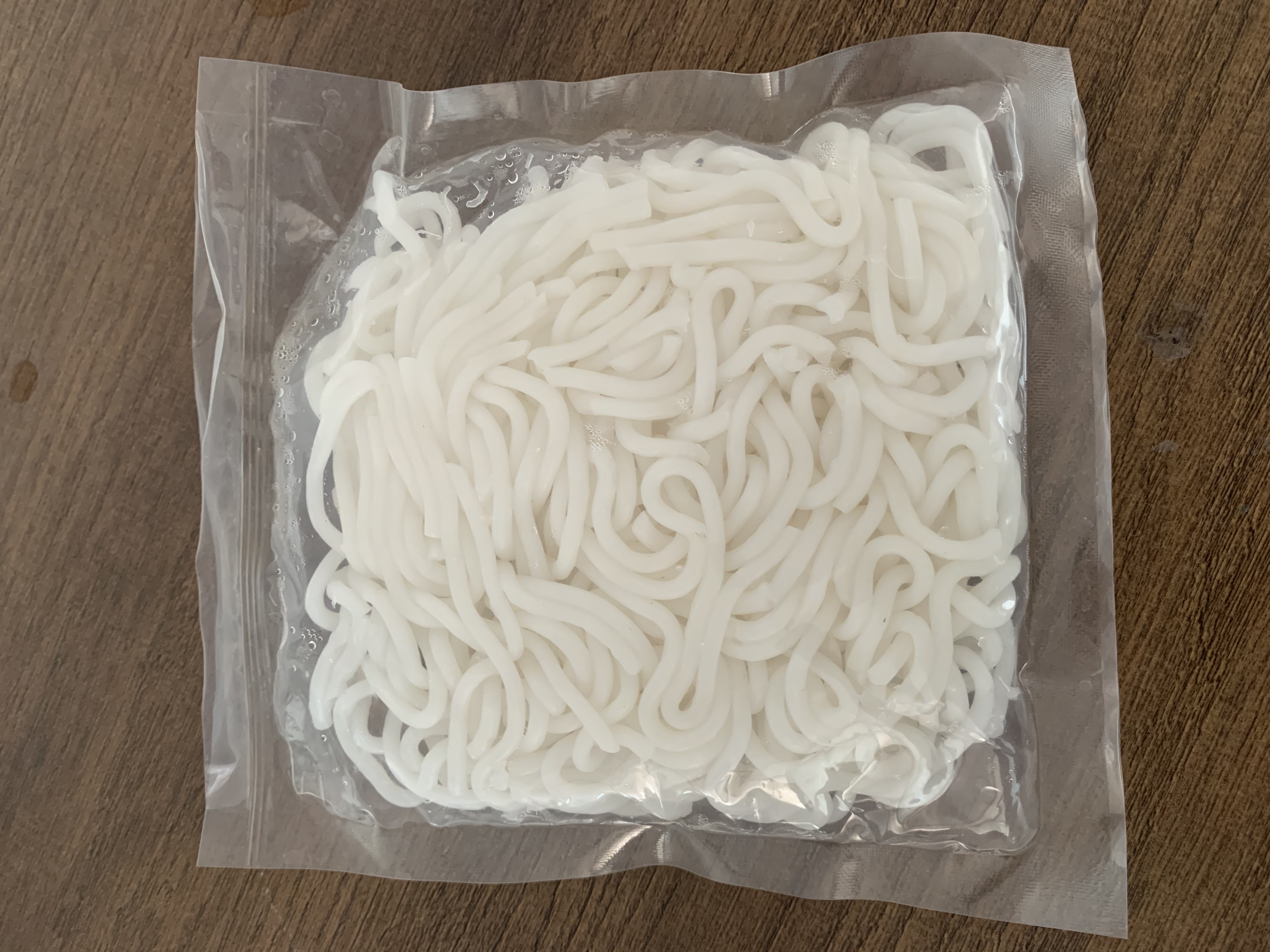

1. Product specification: 160-200g / bag, 4320 bags / h, and the production capacity is 650-850kg / h.

2. 10 hours per shift, 9 hours of production, 13 employees per shift, the yield is 14T of semi dry rice noodles in two shifts.

Technical Parameters:

| Voltage | 380V |

| Water consumption | 3T/T rice noodle |

| Power consumption | 380 degrees/ T rice noodle |

| Air consumption | 2.3T/T rice noodle |

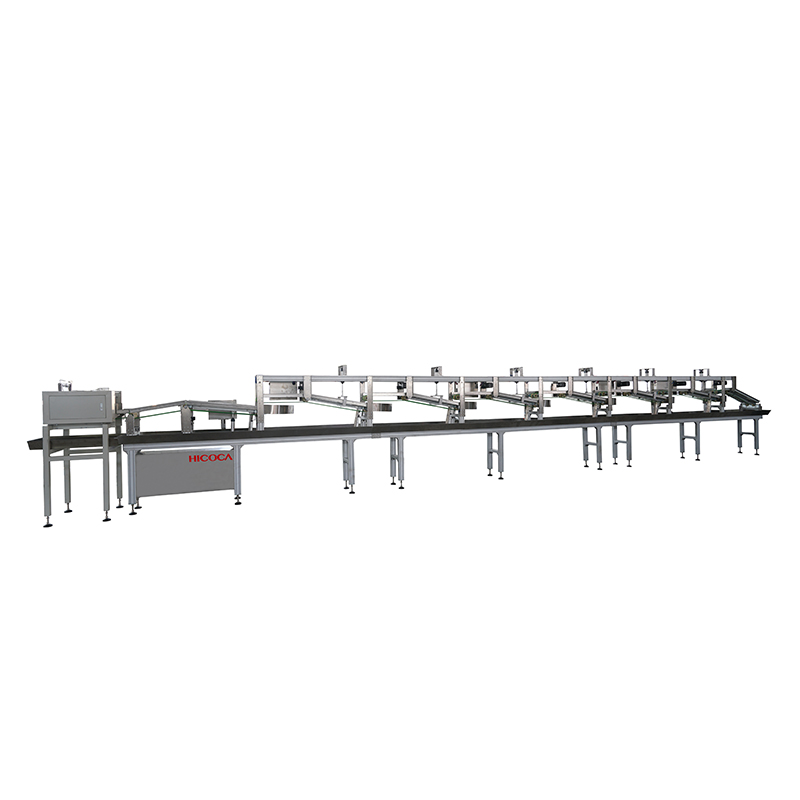

The Rice Noodle(including fresh, semi-dry and instant rice noodles) intelligent production line achieves the automation of the whole line without manual assistance of rice soaking, crushing, extrusion, cutting, quantitativeness, sorting into boxes, aging, softening, disinfecting and drying. It greatly reduces the potential danger of food safety and labor intensity and improves the economic benefits of customers. It makes a breakthrough in the market. We provide customers with the whole process of turnkey engineering from plant layout design, production prediction, product structure adjustment, equipment selection and after-sales maintenance.

About us:

We’re a DIRECT factory specialized in designing and manufacturing full sets of intelligent food production and packaging assembly lines, including intelligent equipments of feeding, mixing, drying, cutting, weighing, bundling, elevating, conveying, packaging, sealing, palletizing, etc. for dried and fresh noodle, spaghetti, rice noodle, incense stick, snack food and steamed bread.

With over 50000 square meters manufacturing base, our factory is equipped with the world’s advanced processing and manufacturing equipments such as laser cutting machining center imported from Germany, vertical machining center, OTC welding robot and FANUC robot. We have established a complete ISO 9001 international quality system, GB/T2949-2013 intellectual property management system and applied for more than 370 patents, 2 PCT international patents.

HICOCA has over 380 employees, including over 80 R&D personnel and 50 technical service personnel. We can design machines according to your requirements, help to train your staff and even send our engineers & technical staff to your country for after-sales service.

Pls feel free to contact us if you’re interested in any of our products.

Our products

Exhibitions

Patents

Our Foreign customers FAQ:

FAQ:

1. Q: Are you trading company?

A: We are a manufacturer of food making and packing machines with 20 years experience, and more than 80 engineers who can design machines according to your special request.

2. Q: What is your machine packing for?

A: Our packing machine is for many kinds of food, chinese noodle, rice noodle, long pasta, spaghetti, incense stick, instant noodle, biscuit , candy, sause, powder, ect

3. Q: How many countries have you exported to?

A: we have exported to more than 20 countries, such as : Canada, Turkey, Malaysia, Holland, India, etc.

4. Q: What is your delivery time?

A: 30-50days. For special request, we can deliver the machine within 20 days.

5. Q: What about aftersales service?

A: we have 30 aftersales service staff, who have experiene to provide service overseas to assemble the machines and train the customers’ workers when machines arrive.

Product detail pictures:

Related Product Guide:

We insist on offering good quality generation with very good business enterprise concept, honest income as well as best and fast assistance. it will bring you not only the premium quality product or service and huge profit, but probably the most significant is usually to occupy the endless market for Factory For Fettuccine Maker - Automatic Semi Dry Rice Noodle Making Machine Production Line – Hicoca , The product will supply to all over the world, such as: Frankfurt, Nigeria, Dubai, We hope to have long-term cooperation relationships with our clients. If you are interested in any of our products, please do not hesitate to send enquiry to us/company name. We ensure that you can be totally satisfied with our best solutions!

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!