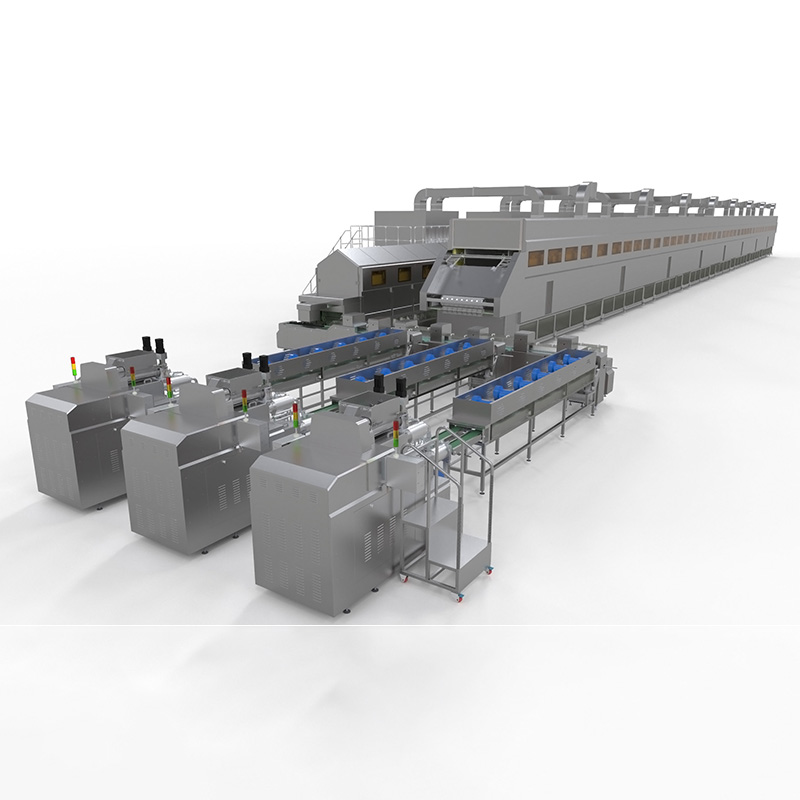

Factory best selling Grey Noodles Packaging Equipment - Automatic Noodle Heat Shrink Packing Machine – Hicoca

Factory best selling Grey Noodles Packaging Equipment - Automatic Noodle Heat Shrink Packing Machine – Hicoca Detail:

Automatic Noodle Heat Shrink Packing Machine Application:

The machine is suitable for multi-layer superposition shrink wrapping of single bag finished products of long strip materials such as noodles, spaghetti, rice noodles, vermicelli and Yuba. The whole process of shrink wrapping is realized through automatic feeding, aligning, sorting, layered stacking and film covering. Technical Specification:

| Power | 1P 220V /3P 380V 50-60Hz 32KW |

| Weight of each big pack | 10~30KG |

| Qty. of bags in each big pack | 8~30 bags/pack |

| Layers in each big pack | 2,3,4 layers |

| Packing speed | 5-15 big packs/min |

| Dimension | 9000L x 2500W x 2200H mm |

| Popular packing layout in each big pack | 5 bags per layer, 4 layers |

| 6 bags per layer, 2 layers | |

| 6 bags per layer, 3 layers | |

| 10 bags per layer, 2 layers |

Highlights:

1. Learning from the design concept of large packaging at home and abroad, we have optimized the design in combination with the characteristics of the principal food industry.

2. The number of packages can be selected according to the demand (for example, 5 single products in each layer, 4 layers superposed, and 20 single products are shrunk in each large package.)

3. Automatic material turnover device is added at the feeding end to facilitate separate code spraying. Large space is reserved to facilitate the aligning, sorting and layered stacking of large volume packages.

4. Antiskid device is added at the end of finished product conveyor. The opening device is convenient for end stacking, and the closing device can be connected with other finished product conveyors for transportation.

5. The daily capacity of single equipment is 80-100 tons, saving labors of 5-8 workers.

6. The equipment replaces finished packaging bags with roll film, saving 400 – 500 CNY per day.

Product detail pictures:

Related Product Guide:

"Control the quality by the details, show the power by quality". Our enterprise has strived to establish a remarkably efficient and stable team team and explored an effective excellent control system for Factory best selling Grey Noodles Packaging Equipment - Automatic Noodle Heat Shrink Packing Machine – Hicoca , The product will supply to all over the world, such as: Adelaide, Canada, Namibia, Our products are mainly exported to Southeast Asia, the Middle East, North America and Europe. Our quality is surely guaranteed. If you are interested in any of our products or would like to discuss a custom order, please feel free to contact us. We are looking forward to forming successful business relationships with new clients around the world in the near future.

On this website, product categories is clear and rich, I can find the product I want very quickly and easily, this is really very good!