Commercial Udon Making Machine

Product Overview

|

Highly integrated

|

|

Easy operation

|

|

Capacity 200 servings/hour

|

|

0 additive

|

1.Mix the dough by hand, mix thoroughly, and blend the water and surface.

2.The dough aging process lasts up to 10 hours twice to stimulate the protein and awaken the vitality of the dough.

3.Five times of adjustment and superposition to form a tight and tough mesh gluten.

4.12-stage intelligent bionic rolling to prevent gluten damage, and repeatedly roll vertically and horizontally to make the noodles chewy and smooth.

5.One-button setting, uniform cutting, adjustable width, can make a variety of noodles such as plain noodles, udon noodles, knife-cut noodles, stewed noodles, etc.

Equipment parameters

|

Capcity |

Mixing machine capaciry |

Machien weight |

Power |

Dimension |

Power supply |

|

250~300 portion/hour |

12.5 kg/batch |

470 kg |

1.5 kw |

1335*880*1365mm |

220V 50Hz |

Technological process

Dough mixing

Dough aging

Dough Pressing

Dough aging

Noodle collecting

Cutting

Dough rolling

Service content

01

Intelligent control

02

One-button setting

03

High-integrated

04

1m³ Noodle shop

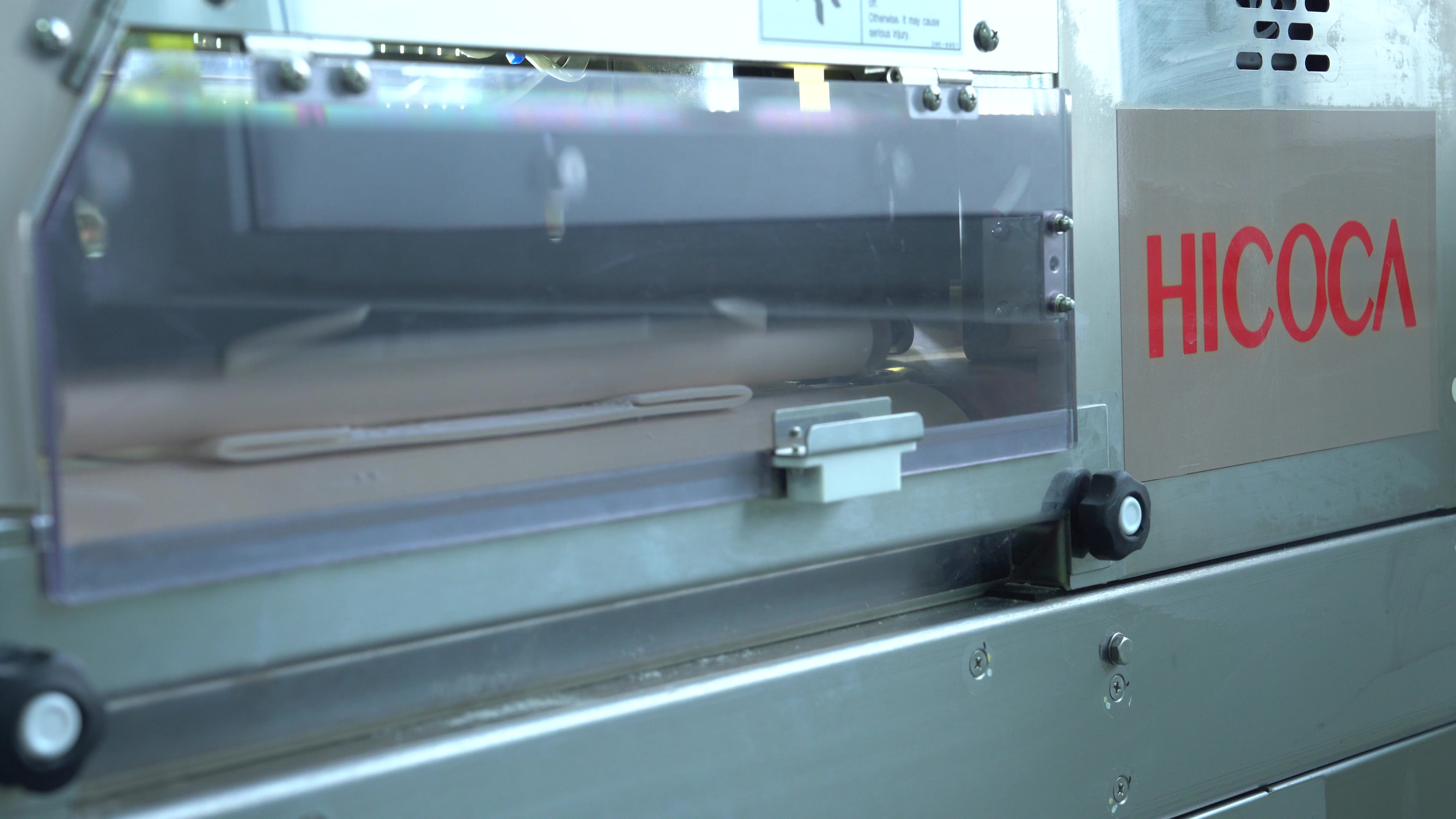

Introduction to Core Equipment

Dough mixing section

The mechanical structure design follows the "artificial imitation" characteristics. In the dough kneading process, the stirring rod is constructed like a finger, making a stirring action similar to that of a human, so that it can stir quickly and evenly, allowing the water and dough to fully blend.

The dough kneading process takes 5 minutes, and 15 kg of dough is kneaded each time. Water is added twice, and the first time the water is added and stirred for 3 minutes, so that the flour and the solution are combined and the dough is kneaded continuously to begin to produce gluten tissue.

After the second water addition, the small particles begin to stick together and become larger. The stirring time at this stage is 2 minutes. This can avoid damage to the dough and make the dough continue to reach the best state of loose particles, uniform particle size, uniform color, full toughness, hand-held into a ball, and lightly rubbed into particles.

Rice noodle cake extruding machine

In the production process of fresh noodles, aging of the dough is a very important step. The dough will be aging twice, both for dough and dough pieces, using a constant temperature and humidity chamber, for more than 8 hours. This process will better combine water and flour, allow the dough to exhaust, relieve the pressure of gluten, and activate the enzyme. The measurement results of the second aging treatment show that the hardness, elasticity and chewiness have been improved to a certain extent, which greatly improves the taste of the noodles.

Dough pressing section

The dough pressing device reproduces the perfect strength of the traditional "hand kneading" dough. The dough that has been proofed is placed in the dough pressing device for pressing. After the dough is pressed for the first time, it is folded in half and rotated 90°, pressed again, and repeated 5 times.

This stage is the forming process for connecting the gluten tissue with the strong tissue network. Too few forming times will result in the gluten tissue not being able to form a perfect structure. But too many times will destroy the gluten tissue, so the dough pressing device can form a tight network structure well, making the noodles taste more chewy.

Dough rolling section

Rolling the dough is to roll it out gradually at a certain speed without destroying the gluten tissue. According to the dough state, temperature, water addition rate and other conditions, the best rolling effect will be achieved with appropriate rolling pressure.

The bionic udon noodle machine is equipped with a 12-stage shifting device, which adjusts the width of the roller in sections and gradually rolls the dough thin by changing the direction alternately vertically and horizontally. This process makes the moisture of the dough more uniform and the gluten network more compact, laying the foundation for a good taste.

At the same time, a measuring instrument is configured to monitor the thickness of the dough in real time, ensuring the uniform thickness of the fresh noodles in a more intelligent way.

Cutting section

No matter how good the dough is, if the final cutting process is not done well, delicious noodles cannot be made. The thickness and aspect ratio of the noodles are related to the appearance of the noodles after cooking.

The automatic noodle cutting device does not need to rely on intuition and experience when cutting noodles. It can freely and flexibly adjust the width of the cut noodles between 1-40mm to ensure that the noodles can fully absorb the soup, achieve delicious fresh noodles, and fully meet the needs of consumers.

Product Overview

|

Fresh noodle shop |

|

Noodle shop

|

| Canteens

|

|

Chain restaurants

|

|

Super market

|

|

Fresh noodle shop |

The HICOCA bionic udon noodle machine is highly integrated, only takes up 1㎡ of floor space, is easy to operate, highly efficient, and can make 300 servings of noodles per hour. It is a real "one square meter" noodle shop.

The bionic udon noodle machine has a wide range of application scenarios, including noodle shops, canteen group meals, chain restaurants, etc. For noodle shops, this equipment can help you open a shop and start a business. Even if you don't know how to make noodles, you can open a noodle shop. For canteen group meals, employees can also experience the food of "high-end noodle shops" in the restaurant, allowing consumers to enjoy the master-level "hand-rolled noodles" that are freshly made and eaten, with a chewy texture and rich noodle aroma.