China New Product Mini Shrink Tunnel Machine - Automatic Noodle Packing Machine with One Weigher – Hicoca

China New Product Mini Shrink Tunnel Machine - Automatic Noodle Packing Machine with One Weigher – Hicoca Detail:

Automatic Noodle Packing Machine with One Weigher

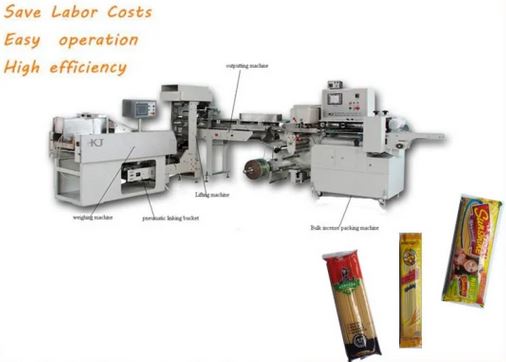

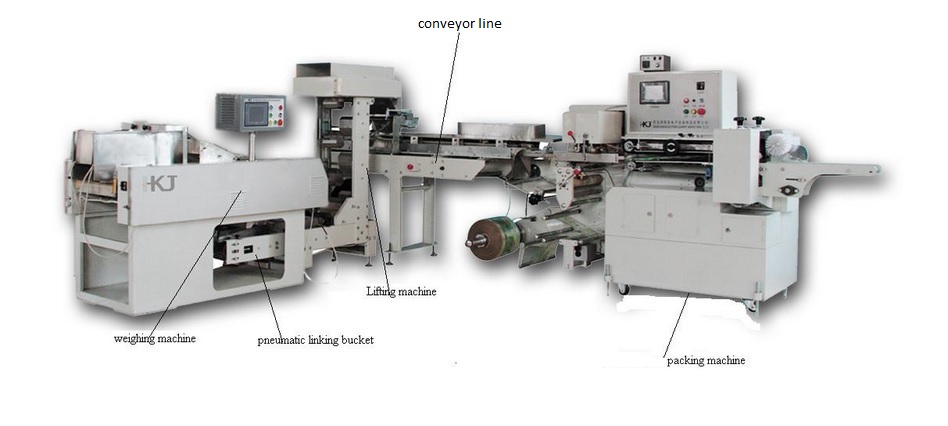

Contents:

1. packing machine: One set,

2. conveyor line: One set(1m),

3. weighing machine: One set,

4. lifting engine: One set ,

5. pneumatic linking bucket:One setApplication:

It is mainly used for packaging of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The packaging process is completed through automatic weighing, output, filling and sealing.Highlights:

1. This is the patented equipment of our factory HICOCA. Round film package facilitates the automation of reorganization, encasement, bagging, storage and transportation of the contents like noodle, spaghetti, etc. In addition, it can protect them from breaking.2. Packing accuracy is highly enhanced by the high speed motion controller and high precision servo driving system. It’s stable and durable.3. It can be operated by one person only and greatly reduces the labor and packaging costs. The daily capacity is 36-48 tons.

4. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

Technical Specification:

| Object: | Noodle, Spaghetti,Incense,Agarbatti,Candle, Rice Noodle |

| Length of noodle | 200g~500g:(180~260mm)±5.0mm;500g~1000g:(240~260mm)±5.0mm |

| Thickness of noode | 0.6~1.4mm |

| Width of noode | 0.8~3.0mm |

| Packing rate | 12-25bags/min |

| Weight range | 200~500g 200~1000g |

| Inputting method | Number input |

| Variable setting: | 0.1g |

| Exact value | 200~500g ,±2.0g-96%; 500~1000g,±3.0g-96%; |

| Size | 3800mmx3400mmx1650mm |

| Voltage | AC220v/50-60HZ/4500W |

Products’ Advantage:

I. Our packing machine uses high-quality imported components, Chinese characters supporting touch screen, PLC, which is easy to operate. Machine speed is controlled by inverter and can work synchronously with other systems. With anti-theft device.

II. Adpot latest technology and massify design. Long operating life.

III. Weighing machine uses Chinese characters supporting touch screen, PLC, which makes the packing speed fast and accurate. It is the perfect substitute product of the traditional packing machine

IV. Spare manpower, Improve productivity: Daily outputting 30t/5 persons

V. Saving material resource.

VI. Reduce the chance of the long-term contact of human body or still can be opposite through food healthy generation harm.

Product detail pictures:

Related Product Guide:

Our growth depends around the superior machines, exceptional talents and consistently strengthened technology forces for China New Product Mini Shrink Tunnel Machine - Automatic Noodle Packing Machine with One Weigher – Hicoca , The product will supply to all over the world, such as: Myanmar, USA, Brazil, Our products have been obtained more and more recognition from foreign clients, and established long term and cooperative relationship with them. We`ll provide the best service for every customer and sincerely welcome friends to work with us and establish the mutual benefit together.

We have been looking for a professional and responsible supplier, and now we find it.