Cheap price Steam Bread Production Line – Multi-Function square steam bread Production Line – Hicoca

Cheap price Steam Bread Production Line – Multi-Function square steam bread Production Line – Hicoca Detail:

Application range

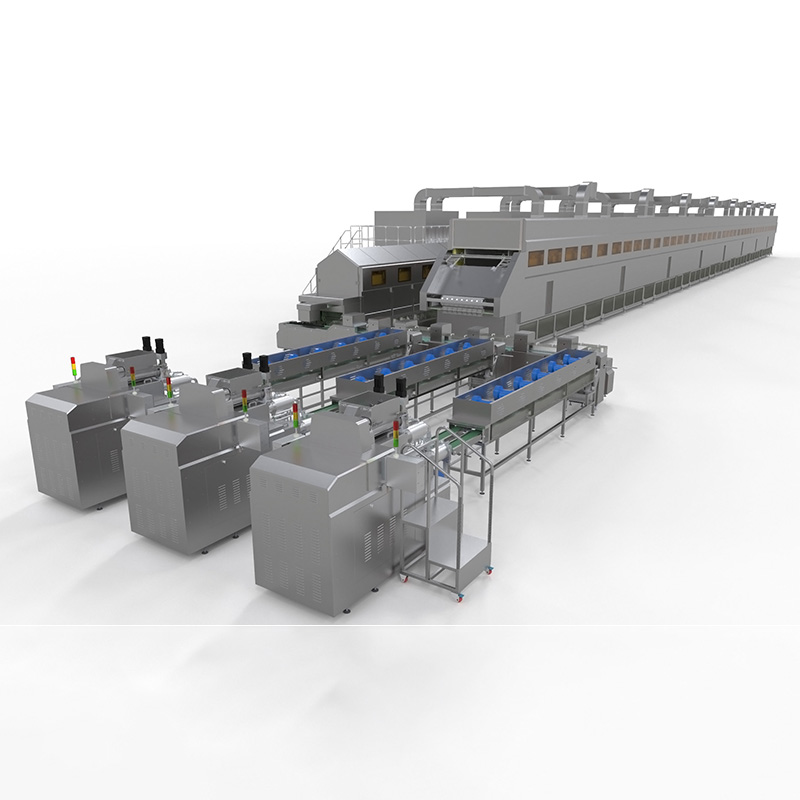

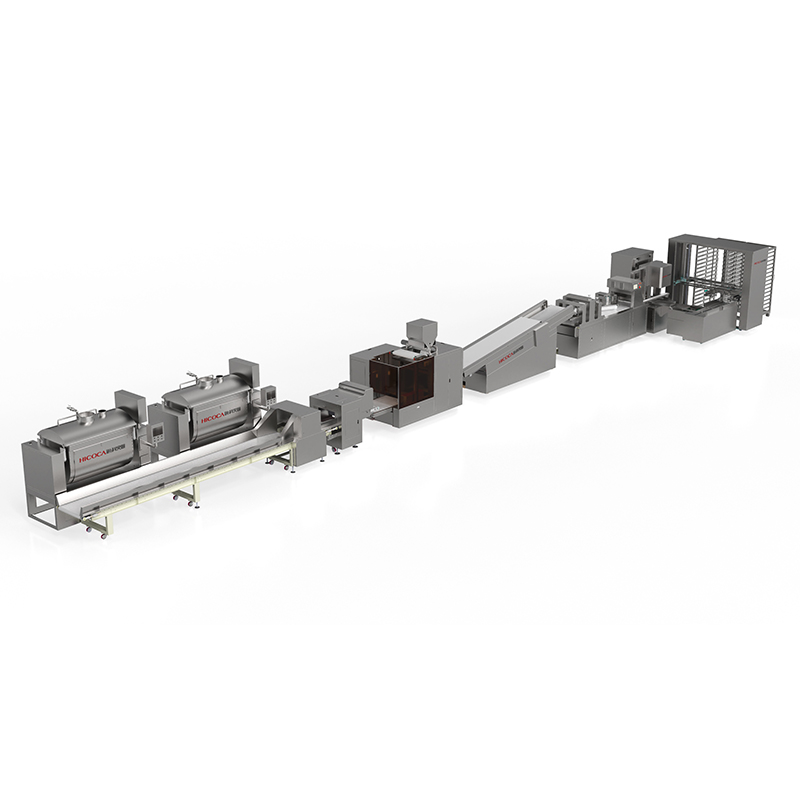

1. Automatic square steam bread automated production line, from raw materials to the cabin finished product automatic production line

Production capacity: Face Product capacity: 0.8-1.2 tons / hour

Process

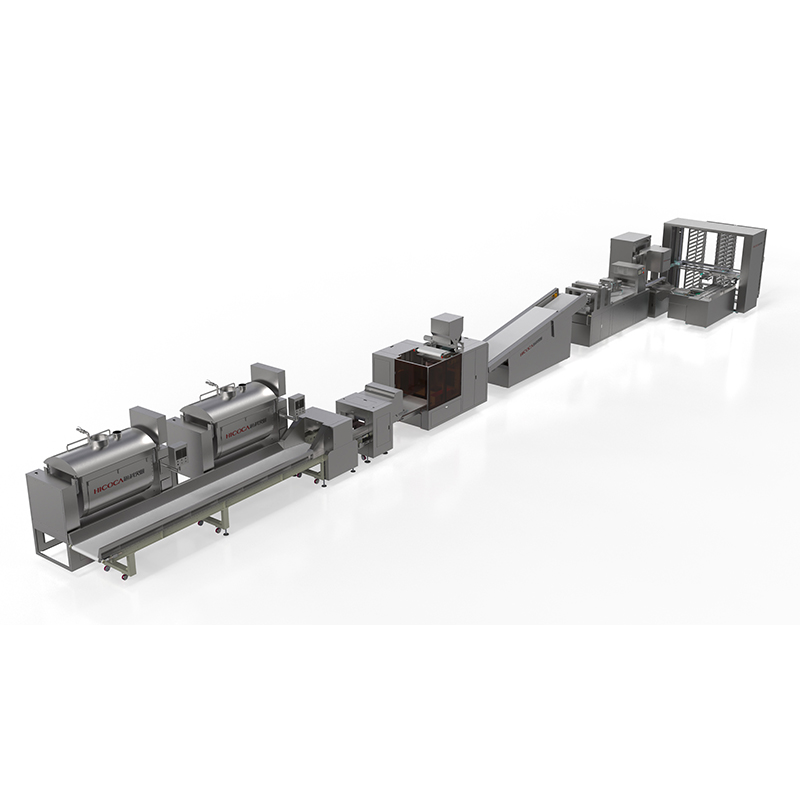

Automatic raw material matching – automatic stirring discharge – quantitative slitting conveyance – imitation worker dough pressure – automatic multi-product molding

Product Highlights

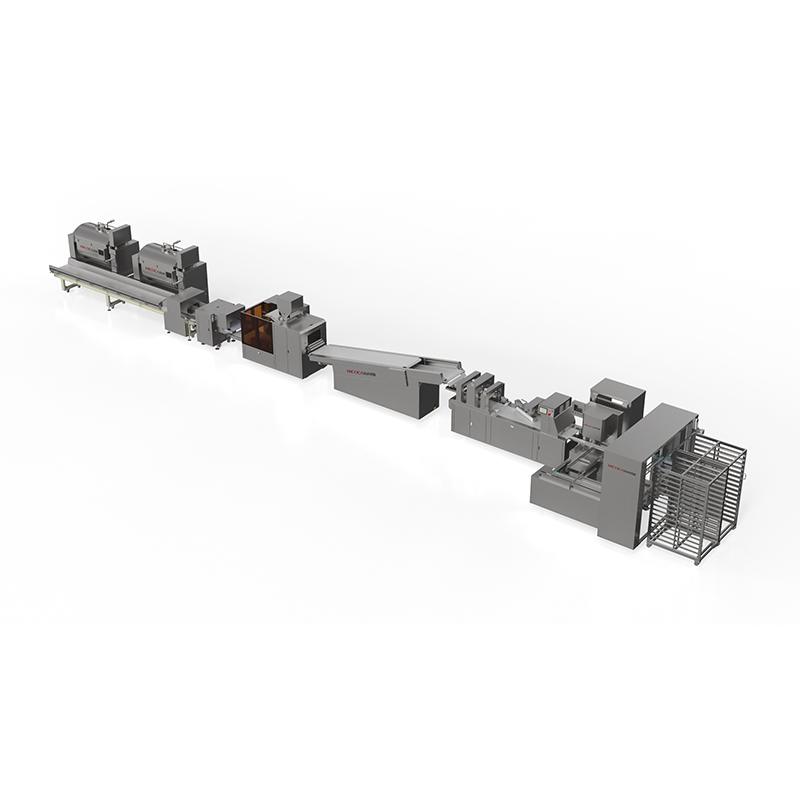

1. High degree of automation, 50% of manual savings.

2. Imitation of hand-painted processes, so that the dough is fully mature, and the finished product tissue is fine and chewed.

3, the production line modular combination, each production line is composed of several functionalization modules, and the functionalization module can quickly achieve the type of product type, so that customers have the most output while investing at the lowest cost.

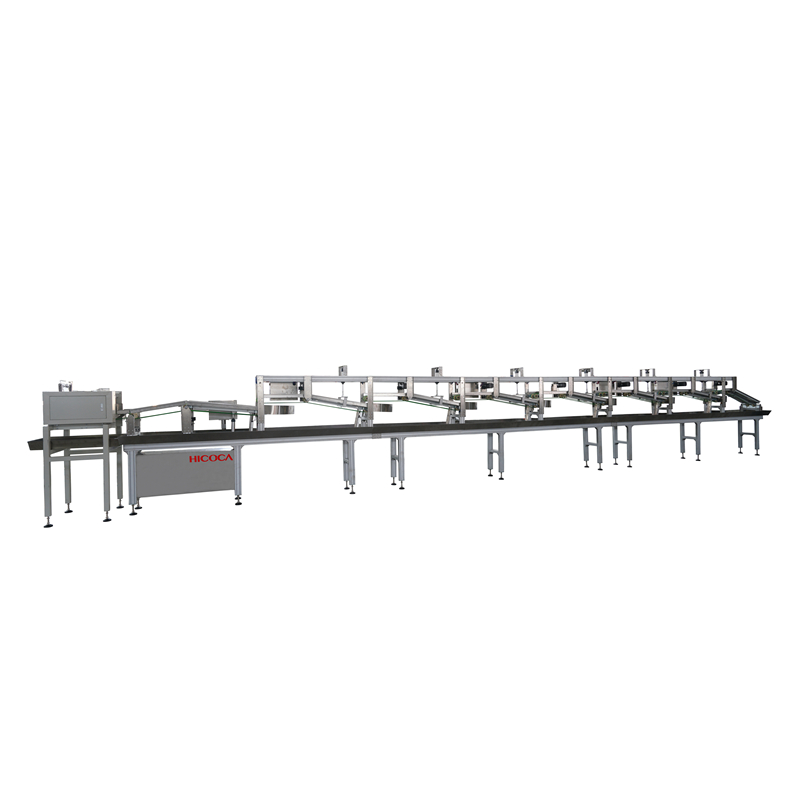

4, multi-node accurate monitoring, servo and frequency conversion combination regulation, realizing the entire line of the production line, the production is smooth, and there is no stackless. Increase the degree of automation, production efficiency, production stability synchronous.

5, the humanized manipulation interface, compatible with a variety of products, while improving convenience, reducing the transfer time and reducing material waste.

6. Detecting elements use high-quality brands at home and abroad, high stability, long service life.

The main parameters

Production capacity: 0.8-1.2 tons / hour

Voltage: 380V

Power: 45 kW

Compressed air: 0.4-0.6MPa

Production line length: customization according to the workshop

Product detail pictures:

Related Product Guide:

Our company puts emphasis on the management, the introduction of talented personnel, and the construction of staff building, trying hard to improve the quality and liability consciousness of staff members. Our company successfully attained IS9001 Certification and European CE Certification of Cheap price Steam Bread Production Line – Multi-Function square steam bread Production Line – Hicoca , The product will supply to all over the world, such as: Algeria, Paraguay, Angola, We always adhere to follow the honesty, mutual benefit, common development, after years of development and the tireless efforts of all staff, now has perfect export system, diversified logistics solutions, thorough meet customer shipping, air transport, international express and logistics services. Elaborate one-stop sourcing platform for our customers!

The accounts manager made a detailed introduction about the product, so that we have a comprehensive understanding of the product, and ultimately we decided to cooperate.