Automatic Noodle Spaghetti Packing Machine

-

Automatic Bag Filling Sealing Packing Machine for Noodle

By selecting different measuring instruments, it’s suitable for the packaging of noodle, spaghetti, pasta, rice noodle, vermicelli, liquid, sauce, granules, powder, irregular blocks and other materials.

-

Two Weighers Automatic Noodle Packaging Machine

It is mainly used for packaging of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The packaging process is completed through automatic weighing, output, filling and sealing.

1. This is the patented equipment of our factory HICOCA. Round film package facilitates the automation of reorganization, encasement, bagging, storage and transportation of the contents like noodle, spaghetti, etc. In addition, it can protect them from breaking.

2. Packing accuracy is highly enhanced by the high speed motion controller and high precision servo driving system. It’s stable and durable.

3. It can be operated by one person only and greatly reduces the labor and packaging costs. The daily capacity is 36-48 tons.

4. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

-

Weighing and packing machine

1, bulk noodle packing machine: one set,

2, conveyor line: one set,

3, weighting machine: three set,

4,lifting engine (elevator):three set,

-

Full automatic bundling and packing machine

automatically finish the process of weighing , bundling, conveying and packing of the noodle and spaghetti.

-

Automatic Noodle Packing Machine with One Weigher

It is mainly used for packaging of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The packaging process is completed through automatic weighing, output, filling and sealing.

1. This is the patented equipment of our factory HICOCA. Round film package facilitates the automation of reorganization, encasement, bagging, storage and transportation of the contents like noodle, spaghetti, etc. In addition, it can protect them from breaking.

2. Packing accuracy is highly enhanced by the high speed motion controller and high precision servo driving system. It’s stable and durable.

3. It can be operated by one person only and greatly reduces the labor and packaging costs. The daily capacity is 36-48 tons.

4. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

-

Automatic Noodle Packing Machine with Three Weighers

It is mainly used for packaging of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The packaging process is completed through automatic weighing, output, filling and sealing.

1. This is the patented equipment of our factory HICOCA. Round film package facilitates the automation of reorganization, encasement, bagging, storage and transportation of the contents like noodle, spaghetti, etc. In addition, it can protect them from breaking.

2. Packing accuracy is highly enhanced by the high speed motion controller and high precision servo driving system. It’s stable and durable.

3. It can be operated by one person only and greatly reduces the labor and packaging costs. The daily capacity is 36-48 tons.

4. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

-

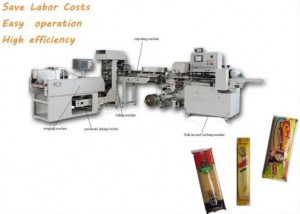

Automatic Noodle Bundling Packing Line with Eight Weighers

The packing line is used for multi bundle plastic packaging of 180mm ~ 260mm long strips of food such as bulk noodles, spaghetti, pasta and rice noodle. The equipment completes the whole process of multi bundle packaging through automatic weighing, bundling, lifting, feeding, aligning, sorting, grouping, conveying, film forming, sealing and cutting.

1. The bundling & packing machine line adopts centralized electrical control, intelligent acceleration and deceleration, and reasonable human-computer interaction.

2. Each line only needs 2 ~ 4 people on duty, and the daily packaging capacity is 15 ~ 40 tons, which is equivalent to the manual daily packaging capacity of about 30 people.

3. It adopts imported electrical components, host frequency speed regulation, servo motor to control sorting, grouping and packaging film transportation, with anti cutting and anti empty packaging functions.

4. It uses film to replace finished packaging bags, which saves material cost of 500-800CNY per day.

5. With accurate counting and good compatibility, it can pack any weight. Equipped with protective devices, the equipment is highly safe.

6. The production line can match four to twelve different quantities of weighing machines according to the demanded capacity. -

Automatic Noodle Heat Shrink Packing Machine

The machine is suitable for multi-layer superposition shrink wrapping of single bag finished products of long strip materials such as noodles, spaghetti, rice noodles, vermicelli and Yuba. The whole process of shrink wrapping is realized through automatic feeding, aligning, sorting, layered stacking and film covering.

1. Learning from the design concept of large packaging at home and abroad, we have optimized the design in combination with the characteristics of the principal food industry.

2. The number of packages can be selected according to the demand (for example, 5 single products in each layer, 4 layers superposed, and 20 single products are shrunk in each large package.)

3. Automatic material turnover device is added at the feeding end to facilitate separate code spraying. Large space is reserved to facilitate the aligning, sorting and layered stacking of large volume packages.

4. Antiskid device is added at the end of finished product conveyor. The opening device is convenient for end stacking, and the closing device can be connected with other finished product conveyors for transportation.

5. The daily capacity of single equipment is 80-100 tons, saving labors of 5-8 workers.

6. The equipment replaces finished packaging bags with roll film, saving 400 – 500 CNY per day.

-

Automatic 3D M-Shape Bag Noodle Packaging Machine

This equipment is suitable for M-shaped three-dimensional bag forming and packaging of 180~260mm long bulk noodle, spaghetti, pasta, rice noodle and other materials. Automatic weighing, bag making, lifting, conveying and other steps to achieve the entire process of automatic three-dimensional bag packaging.

1. Solid forming: As our patented equipment, it realizes the automatic production of top grade three dimensional packaging.

2. Automatic bag making with film achieves different packages varied from 400g to 1000g and reduces costs of labor and film.

3. Reciprocating horizontal sealing makes the sealing dog-ears beautiful.

4. Electrical anti-cutting avoids injury to staff and equipments

5. Function of empty bags detection can prevent empty bags effectively and save the cost of film.

6. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.

-

Three-Dimensional Bag Noodle Packing Machine with High Speed Weigher

Automatically complete the packaging of noodle, spaghetti, long pasta, rice noodle and other strips of food with the processes of weighing, bundling, outputting, filling and sealing.

-

Automatic Noodle Feeding Line

It’s suitable for carrying products with length (180-240mm)*width(0.6-1.4mm) like noodle, pasta, spaghetti, rice noodle etc. and can work with packaging lines.

-

Automatic Pasta Spaghetti Noodle Weighing Packing Machine with One Weigher

It is mainly used for packing of 180 ~ 260mm long loose noodles, Spaghetti, Pasta, Rice noodles and other long strips of food, candle, incense stick, Agarbatti, etc. The packing process is completed through automatic weighing, output, filling and sealing.

1. This is the patented equipment of our factory HICOCA. Round film package facilitates the automation of reorganization, encasement, bagging, storage and transportation of the contents like noodle, spaghetti, etc. In addition, it can protect them from breaking.

2. Packing accuracy is highly enhanced by the high speed motion controller and high precision servo driving system. It’s stable and durable.

3. It can be operated by one person only and greatly reduces the labor and packaging costs. The daily capacity is 36-48 tons.

4. The qty. of weighing machines in this packaging line can be adjusted according to your required capacity.