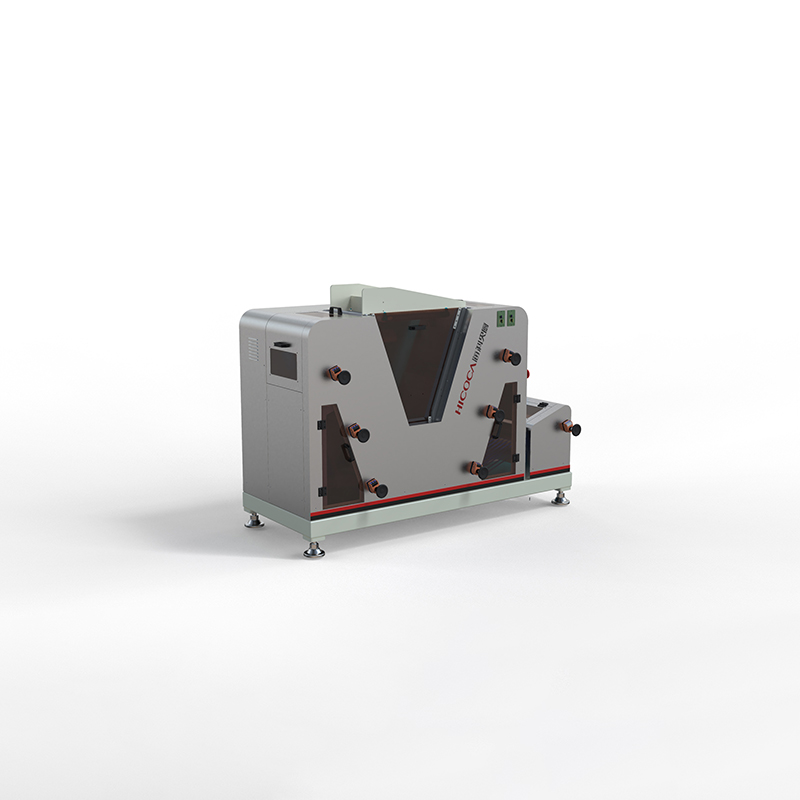

2021 Good Quality Rice Noodle Processing Line - Fresh noodle producing machine – Hicoca

2021 Good Quality Rice Noodle Processing Line - Fresh noodle producing machine – Hicoca Detail:

Scope of application

Automatic production of dough sheet and dough flocculation multi-layer composite fresh wet noodle.

Process flow

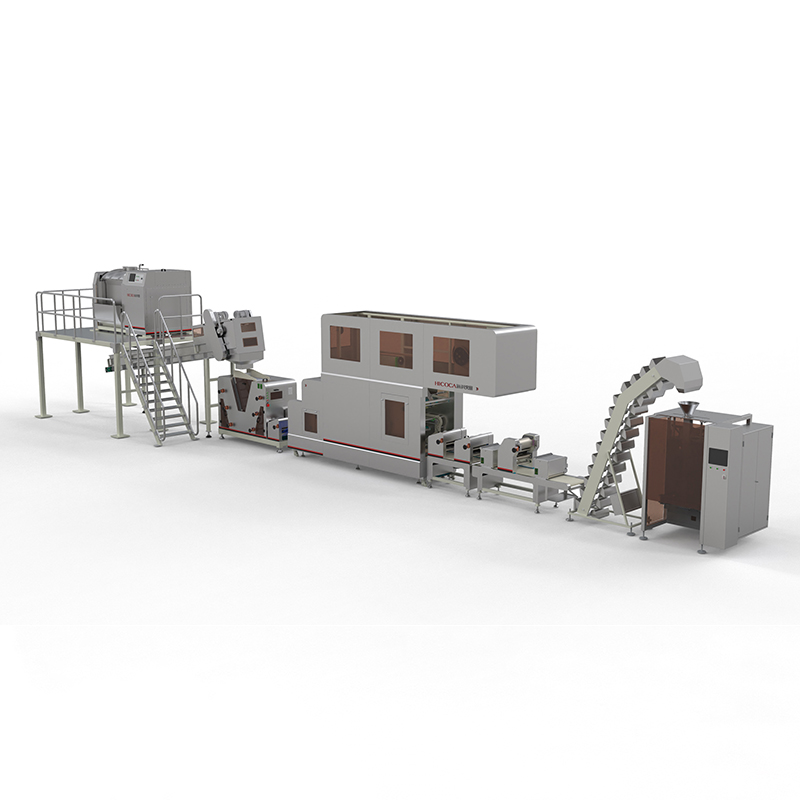

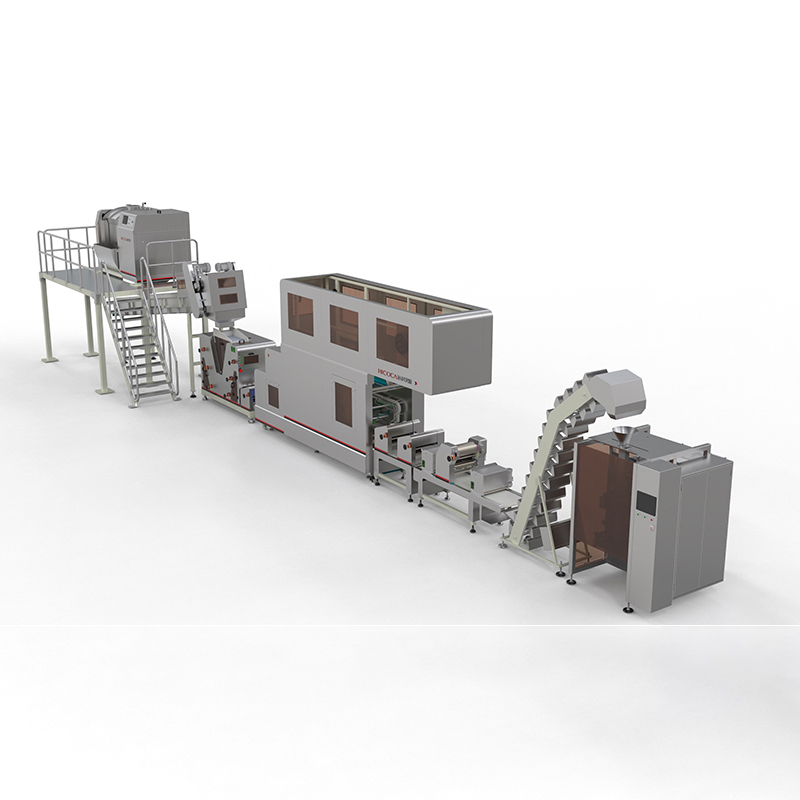

Automatic powder supply-automatic salt water mixing, water supply-kneading-noodle floc maturation-flake composite calendering-noodle mat maturation-continuous calendering-strip forming-packaging

Product Highlights

1. New noodle making technology

The original noodle belt and noodle flocs are compounded and continuously calendered, and the noodle flocculation layer faces the inner side of the two noodles, so that the gluten network is better formed and has a sense of layering. The automatic roll aging for 30 minutes is followed by continuous calendering to form the fresh and wet noodles. Elastic, chewy and smoother.

2. High degree of automation:

The whole process is automatic production without manual intervention from the noodles output from the kneading machine to the packaging of the fresh and wet noodles.

3. Modular combination of production line:

The production line is composed of several functional modules, which can be freely matched according to customer needs and on-site layout, so that customers can have the most output while investing the lowest cost.

4. Excellent quality:

The detection elements are all high-quality brands at home and abroad, with high stability and long service life.

The main parameters

Maximum production capacity: 600kg/h

Width of pressure roller: 350mm;

Power: 35kw

Air source: 0.6-0.7Mpa

Floor area: 15m×2.5m=37.5m²

Product detail pictures:

Related Product Guide:

Fast and great quotations, informed advisers to help you choose the correct solution that suits all your requirements, a short creation time, responsible top quality manage and distinct providers for paying and shipping affairs for 2021 Good Quality Rice Noodle Processing Line - Fresh noodle producing machine – Hicoca , The product will supply to all over the world, such as: Melbourne, Houston, Vietnam, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will offer our best service to satisfy all your needs! Please contact us right away!

Wide range, good quality, reasonable prices and good service, advanced equipment, excellent talents and continuously strengthened technology forces,a nice business partner.